Machining of journals

Renovation and repairing often take up a lot of time and are very expensive. This is because the long-lasting and intense exploitation of the deteriorating basic working conditions, and the condition of each part of a machine is far from correct. Not inevery case, a simple replacement of worn parts allows you to restore the demanded working plan. Some elements require the use of mechanical machining.

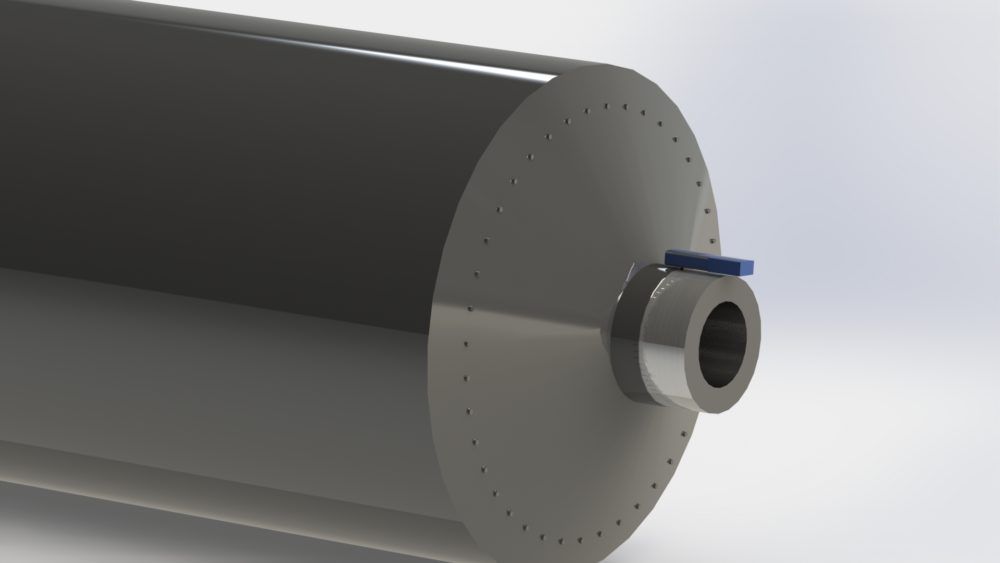

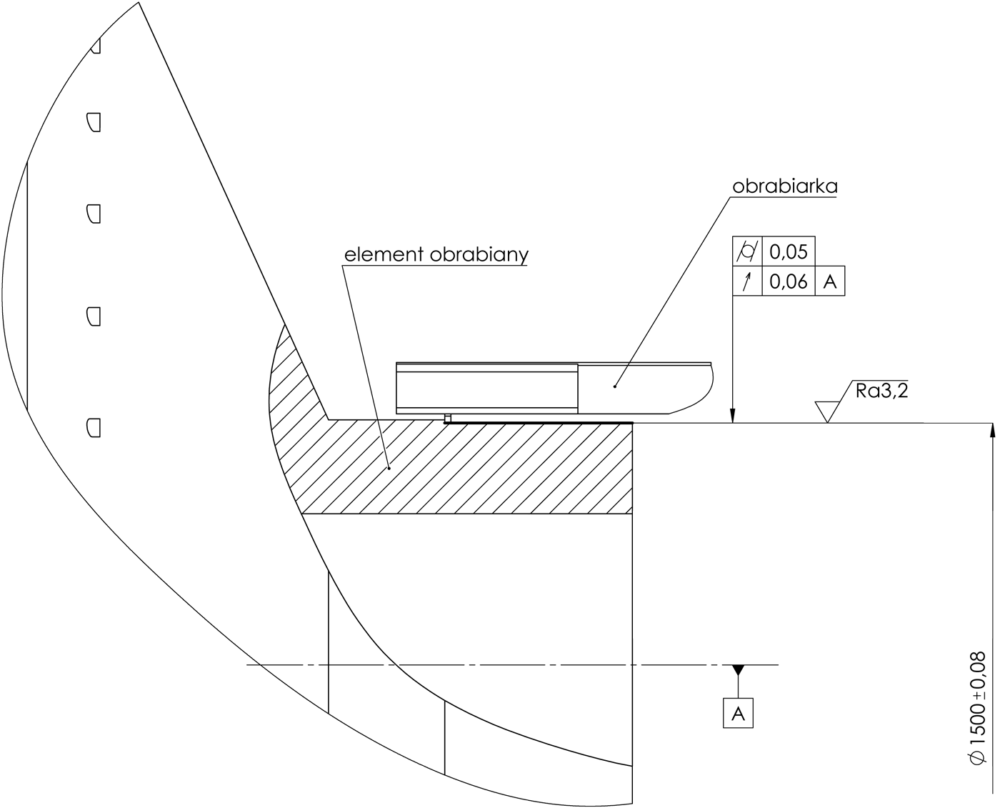

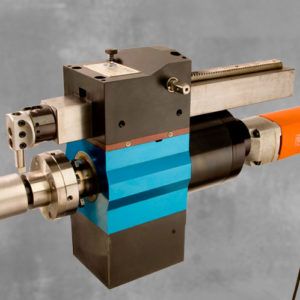

The on site machining by portable lathes, which are mounted directly on the treated part of the machine, has a number of advantages to help you get back to the standard parameters. Fault location is often hard-to-reach places, to the heavy, large-scale assembles with heavy loads. For our technology, such obstacles are not a problem. On the contrary, each new job is an opportunity to show the possibilities of fully compact machine park and qualified personnel.

Any kind of shape errors, lack of tolerance to the bearing, or its scoringare situations where our method of operation is ideal. Removing corrosion and cracks, and return to the correct alignment of the element, and the elimination of clearance for the bearing are effects we receive after you apply our procedures, without long waiting time and dismantling of reconditioned parts.