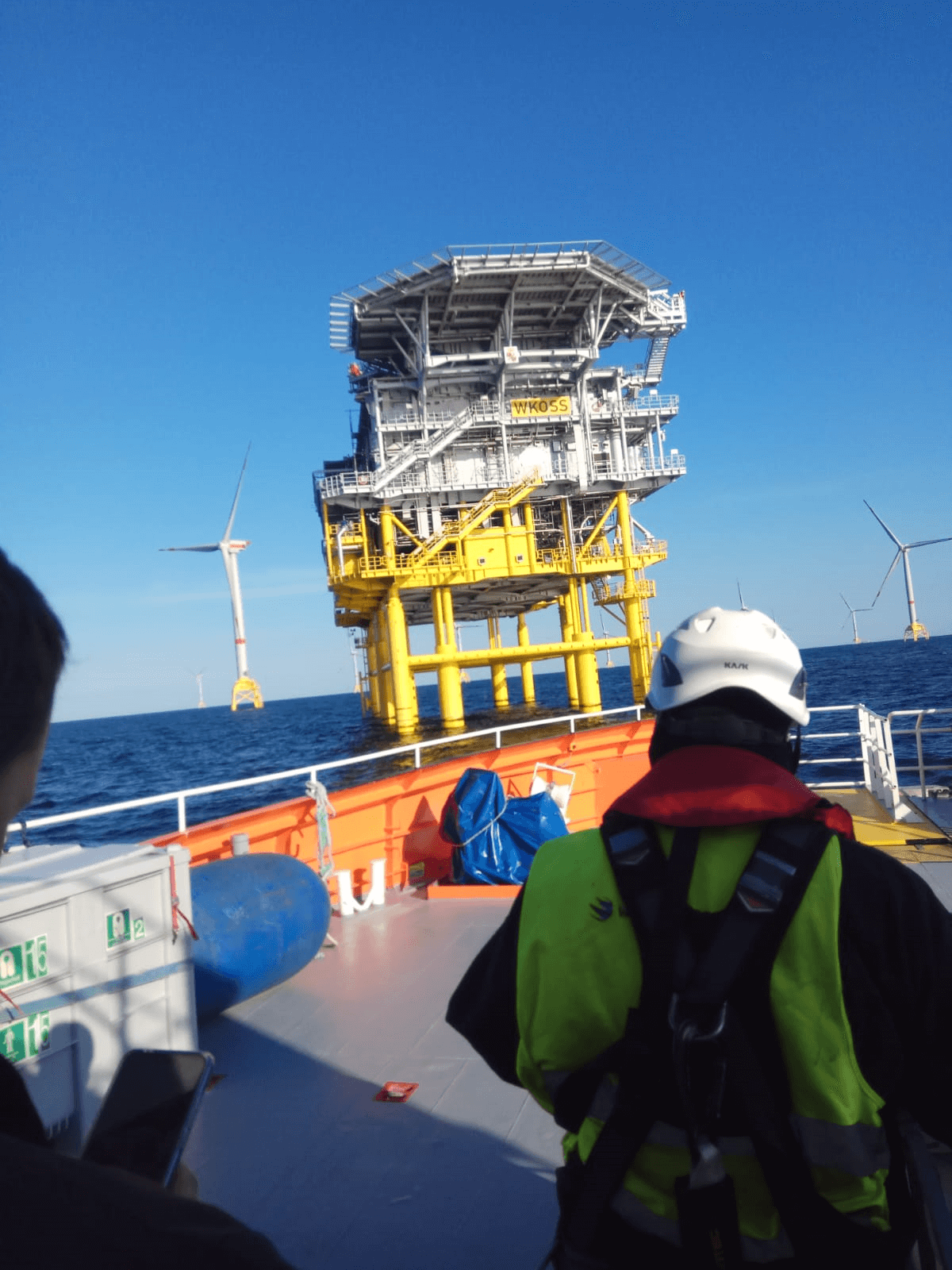

In September, our specialists completed a very special project in the middle of the Baltic Sea on OSS WIKINGER wind farm in Germany. The task that was oreded by Norwegian company was to perform machining of the pedestal collar, and we had been given only 24h for its implementation. WWTECH obtained special permits and pass the necessary trainings to work on the platform.

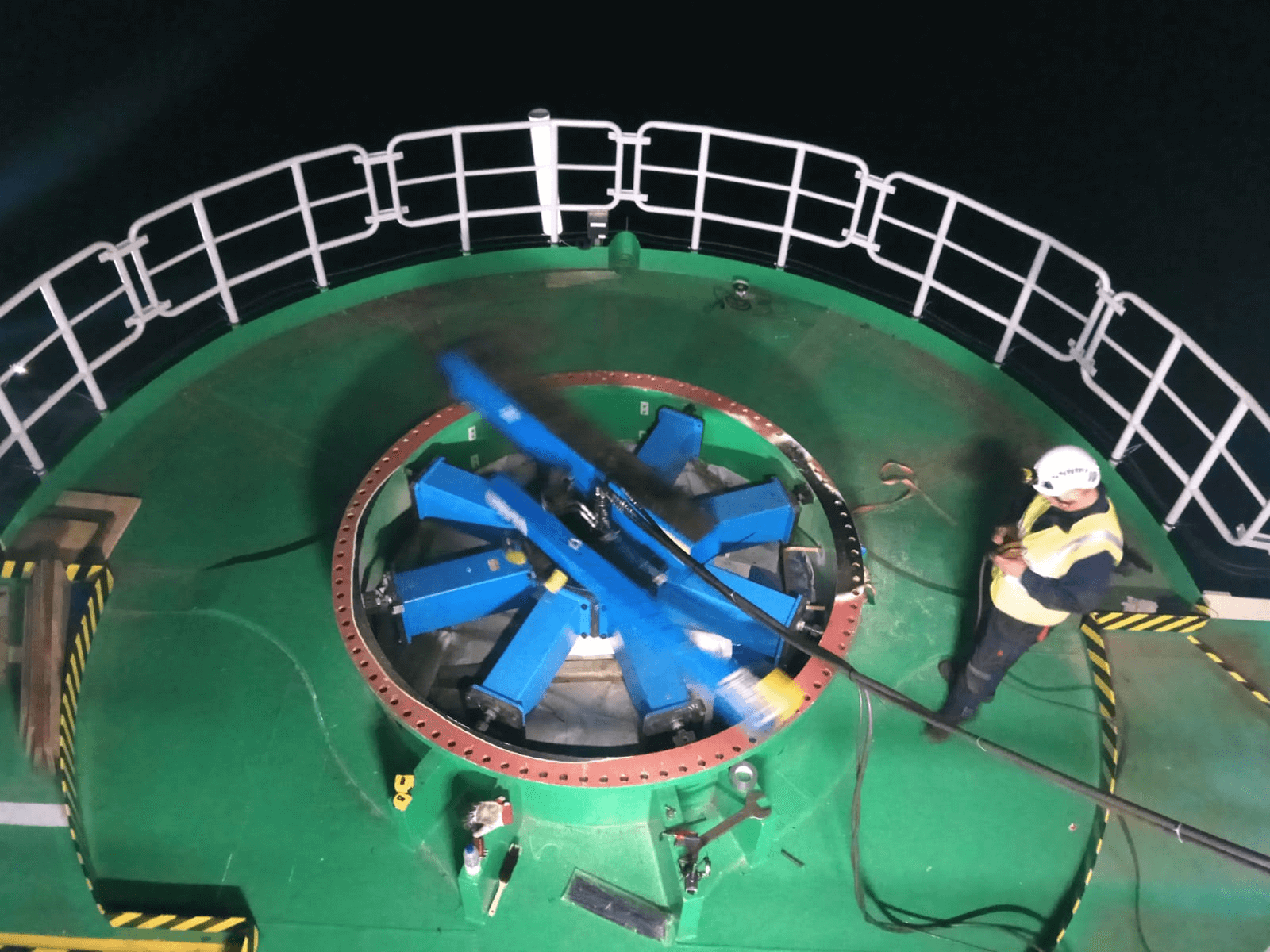

A machine dedicated to this work was assembled and prepared in port in Gdynia. The equipement with our team was later taken by a specialmarine unit, Jack-Up type (self-elevating vessel).

After reaching the work site, the WWTECH team regenerated damaged surface of the radial foundation with a diameter of 3000mm, achiving flatness of new surface below 0.1mm (0.5mm required). Our company is able to perform, a.o.: flange machining of wind towers with a diameter of over 7000mm.

The whole service was done in the middle of the sea within 20 hours, away from the workshop with large-size machining tools!

The obtained quality was confirmed by engineering measurements using Laser Tracker.

This is another work carried out for the Offshore sector and again our company has met all technical and formal requirements.