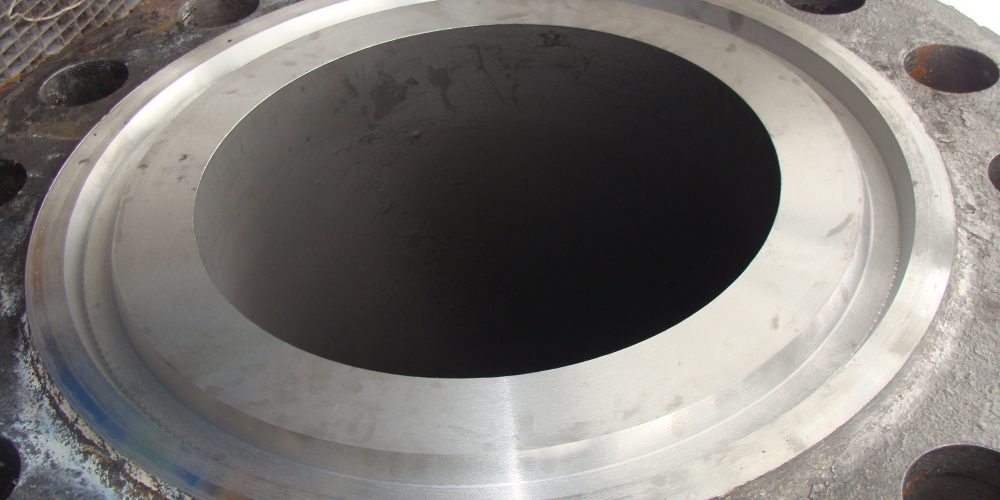

Our client has decided to modernize the screw connection of the turbine flanges. In place of the traditional connection with stud bolts crewed into the lower half of the cosing, it was decided to make through holes with a slightly larger diameter than the original solution. In the first step, due to the shape of the casting, a feasibility study had to be carried out – for this purpose, a 3D scan of the flanges was performed, with a particular focus on the radii of the transition to the casing area. The result is a three-dimensional model of the casing’s fragment within the area of planned upgrade. On the same […]

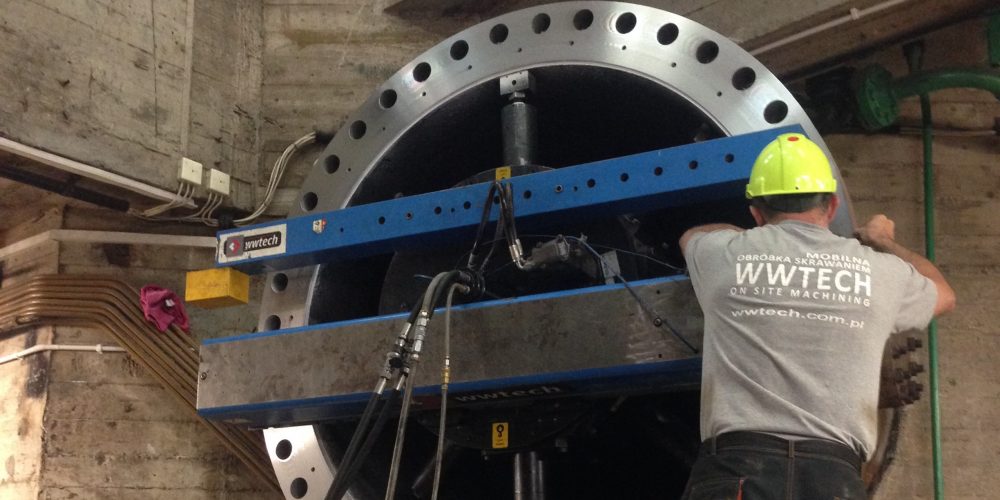

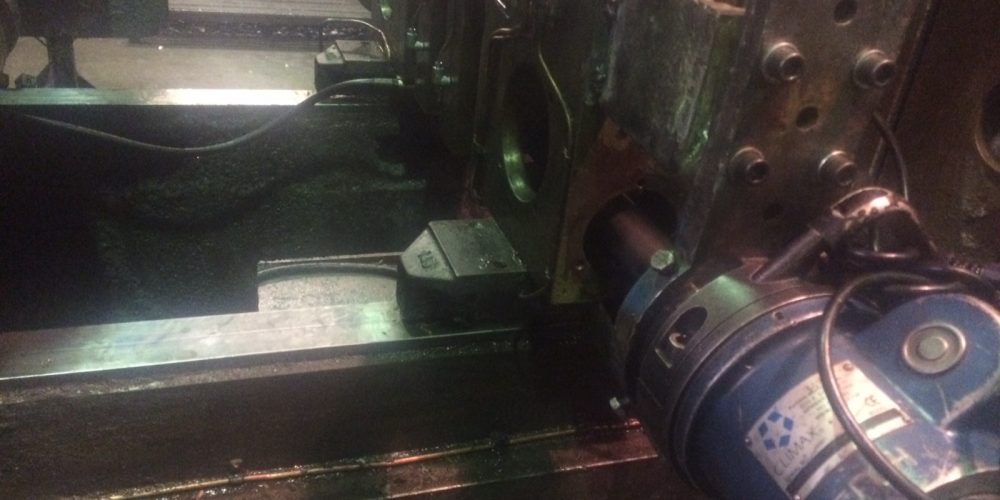

Solutions of „in-situ” maching created by WWTECH Services’ engineers let restore the delivery condition of threaded connections in final drive for roll stand.

Once again our specialists proved their efectivness of on-site machining in hydropower stations.

WWTECH Services team has made an legalization of cut-valve’s surfaces in pumped storage water power plant in Poland.

WWTECH was done the machining of the key surfaces in steam turbine’s cut-off valves.

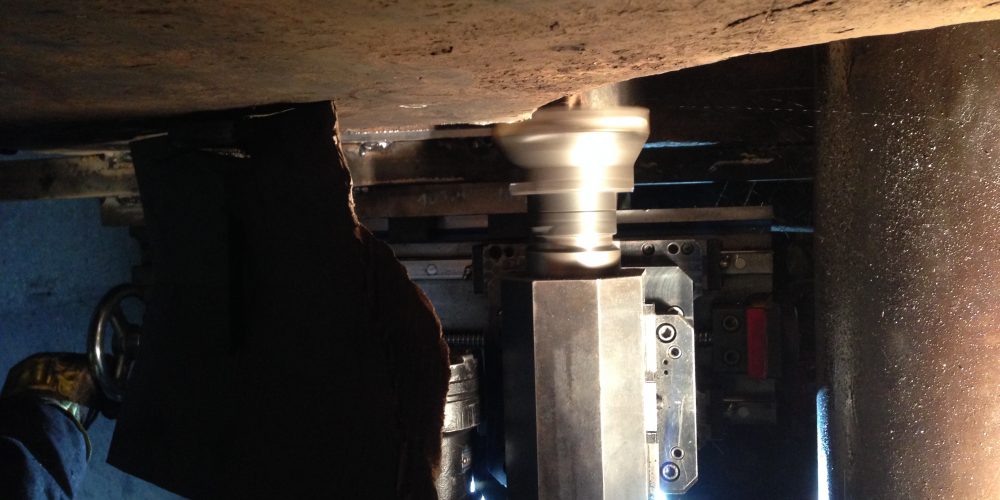

Specialists of WWTECH thanks to on site machining solutions and making precise coordinate measurements restored the right working of the locking system in the molding press.

The lack of shape mistake of groove and of center hole of traverse is a condition of the right operate of press forging.

The pads on the heat exchanger flanges – On site machining WWTECH carries out the works in ORLEN Group plants.

Thanks to use on site machining technology WWTECH Services team has done machining of face on the cover of container in petrochemical plant The container modernization by using on site machining let additionally secure it against depressurization. It is extremaly important by virtue of combustible and explosive material.

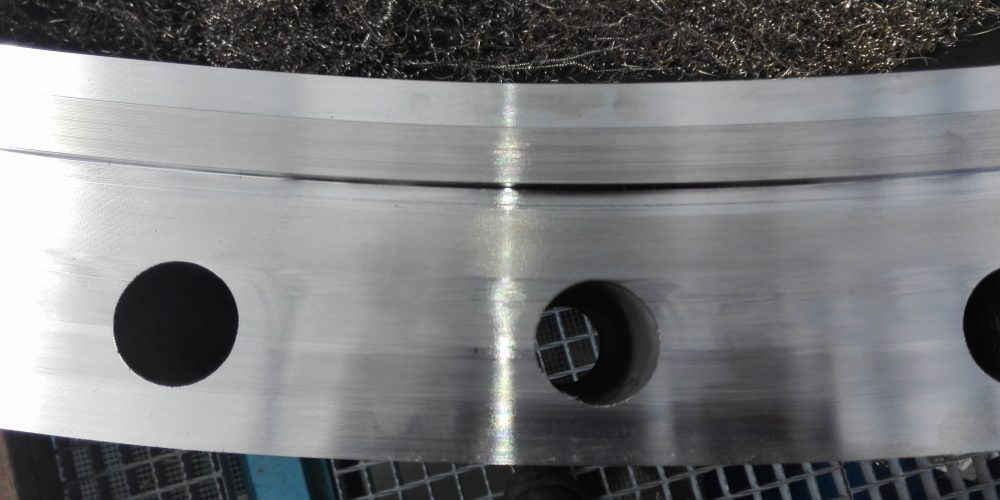

WWTECH SERVICES has completed another repairing project of the foundation in the large-size slewing rings. This time, the task was carried out with the use of the port crane Kone Crist Shipyard Inc. As a result of work, there was obtained the required flatness tolerances of the foundation necessary for the proper operation of the machine. The port cranes are the integral part of the Polish coast landscape. They have become a part of the aesthetics in this part of our country, as well as the history and identity of entire generations of Poles. To ensure an effective work for these devices and enable them the smallest failure in the […]