Hardfacing

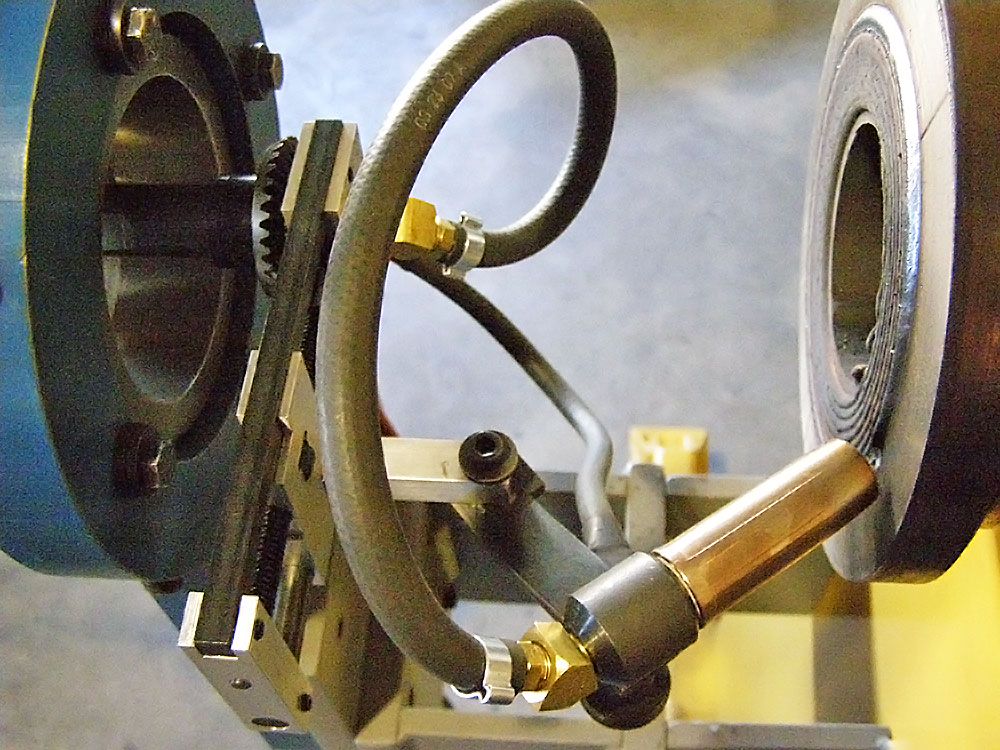

Several times, to ensure proper operations of treated elements or assembles of elements, it is not enough to implement machining as the only solution. Apart from process of drilling, milling or other using portable machinery, there is often a need to apply hardfacing which consists in coating objects in a layer of metal and melting the surface at the same time.

Hardfacing is usually incidental to holes, flanges and flat surfaces regeneration, such as fundaments or shift elements. When the return to the required nominal is not possible due to lack of the necessary amount of the material or when the condition of expected part of specific units fitting is normalizing the series of holes when there is a necessity to add some material. Then, thanks to the welding techniques, achieving these expectations is possible. The advantage of such a solution is the return to the vernacular material, so that there is no need to replacing it with the filling of another origin.

On site machining solutions, enriched of hardfacing, done also with the help of portable machines, find use in every industry branch, especially in heavy industry. Machines working there, are exposed to the influence of large loadings, that is why not only the machining method but also the material subjected to the machining is very significant.