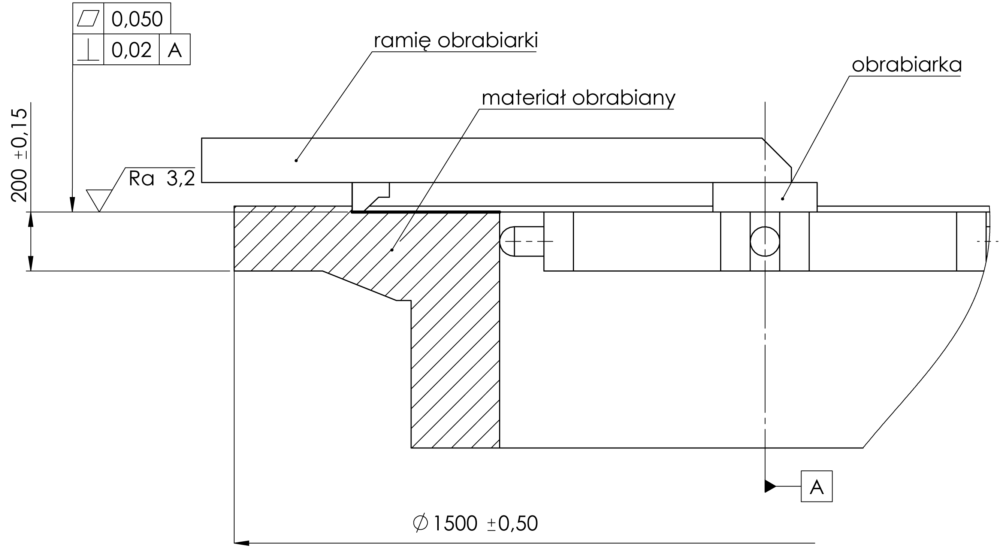

Machining of flanges

The tightness of the connections is a prerequisite for the proper functioning of any industrial installation. Of particular note in addition to the subsequent parts deserve created between them the place of insertion. These connections within the process equipment in chemical plants, nitrogen and petrochemicals and everywhere where there is a high pressure must comply with the very stringent standards. Only their correct maintenance enables trouble-free and safe operation throughout the plant.

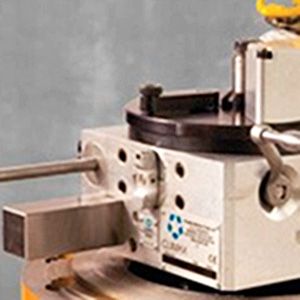

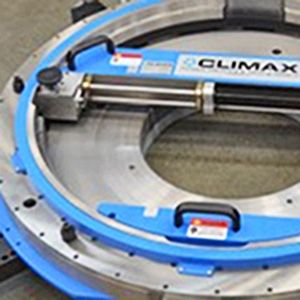

All flange connections, ranging from small to large size, undergo different types of problems and accidents, the effects of which are usually quite severe for the entire enterprise. Repeatedly we are placed at any challenge to rusted, deformed or damaged by the chemical elements of the flanges. Next, there are formed in different ways, leaks and defects in the adjacent surface, curvature or corrosion. The unpredictability of such situation obliges to take rapid and effective response. The same is also at the time of scheduled repairs or upgrades, changes of seals and the liquidation of the deformation of welding parts of such connections. Developed over the subsequent projects procedure allows to face the flange machining challenges regardless of their size and position.

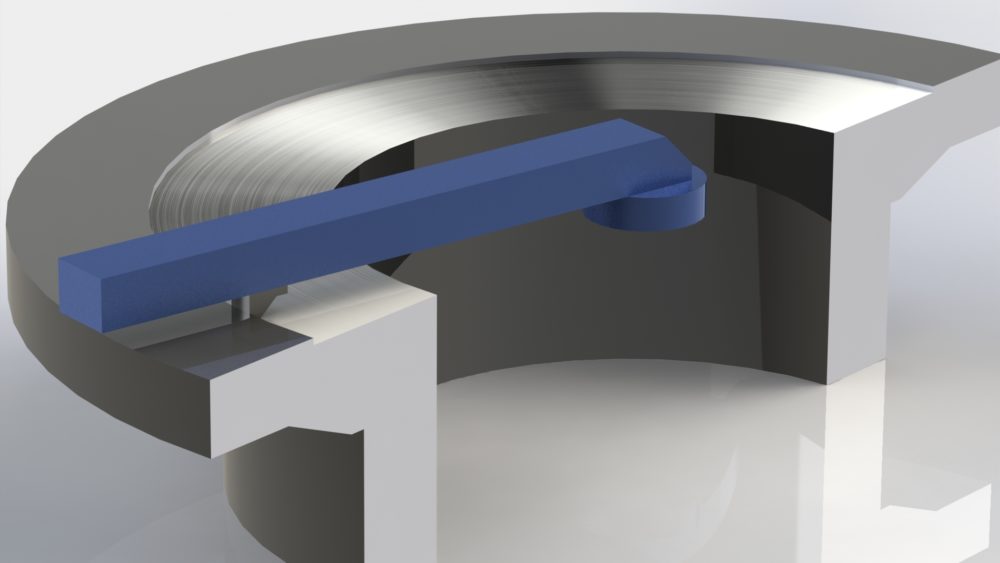

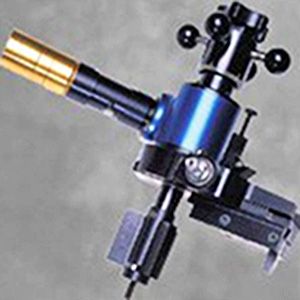

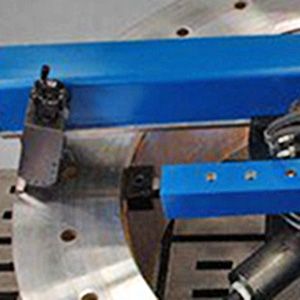

The final result of the use of on site machining methods is to restore full tightness of flanged connections, improve geometrics and surface flatness and the elimination of any losses. An additional advantage of using turning is to obtain the spiral structure of required surface roughness without the diagonal scratch, which could interfere with the hermetic connection. Guarantee due geometry connections we get proper geometry of the whole construction machinery.