Turning of engine lines

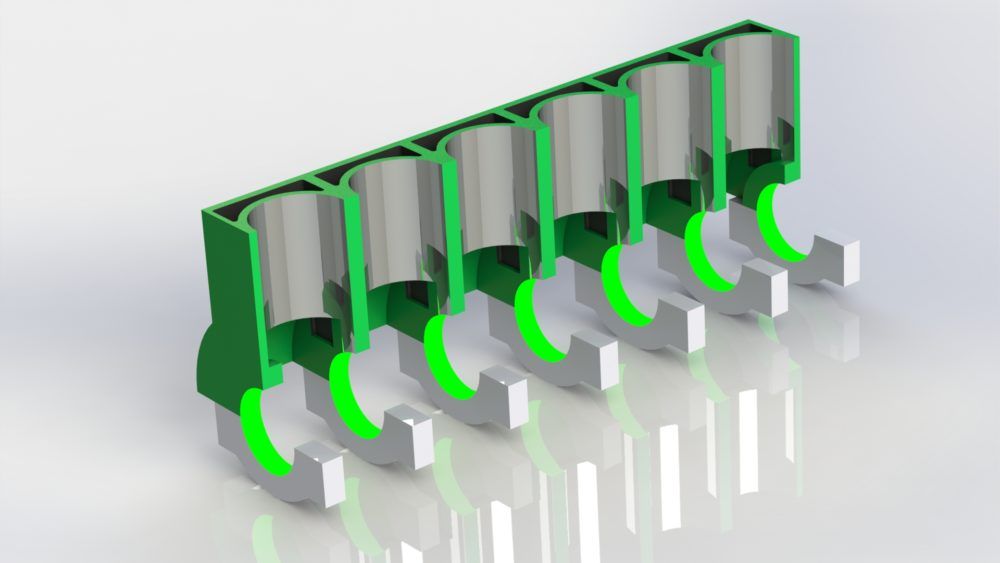

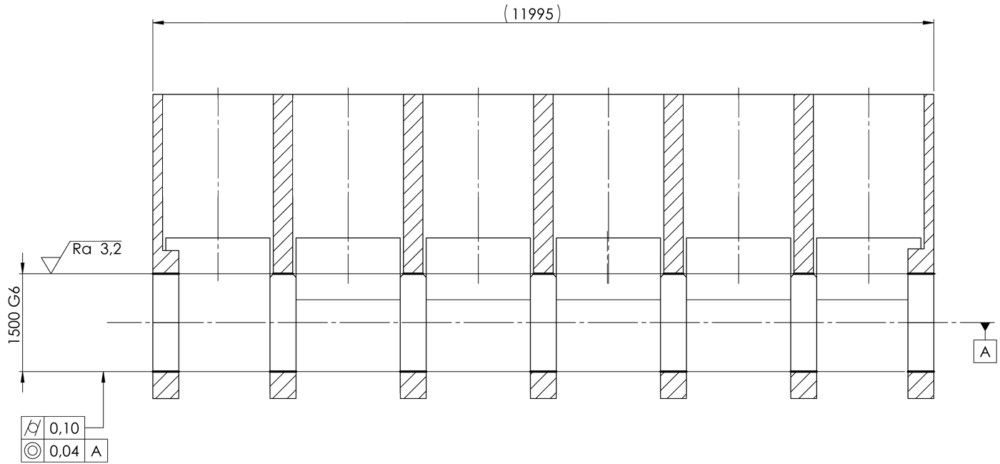

Diesel engines of large size found mostly in ships require repair and modernization solutions, which are not limited to a single developed pattern. One of the ways of action is the on site machining.

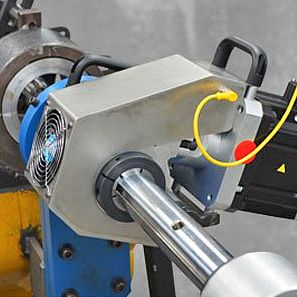

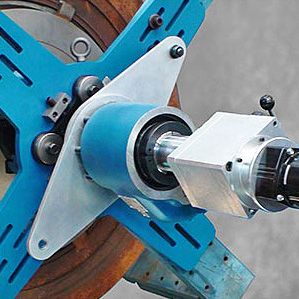

Technology that uses fully compact machinery allows composing each part corresponding to the requirements of the job, no matter what size the treated structures. In addition, the installation of the machine on a particular element allows us to fit even in the most hard-to-reach places, at a much reduced cost of the whole process.

The effect of using procedures of on site technology used by our specialists in conjunction with ongoing evaluation is to restore the original size of the treated parts and holes, restoring a normal structure without any cracks and deformations and the required standards for connections of metals without cracks and damaged to the castings.