Initially only for our own, more and more and more often, we produce special fasteners (not standardized). In our case, our own needs mean mostly customizing mobile equipment to specific cases of service – adaptation the machine to the workpiece, clamping of machining tools, supports or additional bearings.

It turned out that there is a demand for such items, usually previously not foreseen, during dismantling or after treatment. A typical example of such a situation are works by flange connections, when it turns out that some of the screws are simply stuck, and hence, must be destroyed when dismantling.

To meet the expectations, having gathered a lot of experience, we are now able to offer a more comprehensive approach to widely understood screw connections, ranging from dismantling, including disassembly of the destroyed (rough, worn off, blocked in any way) the screws and studs, through correction of geometry and surface quality of the connection, the correction of damaged threads, through the supply of appropriate to the new configuration fasteners (often modified), till final assembly of the connection. Synergy is achieved by reducing the time to prepare elements for production, using current knowledge and prediction of the connection status during processing.

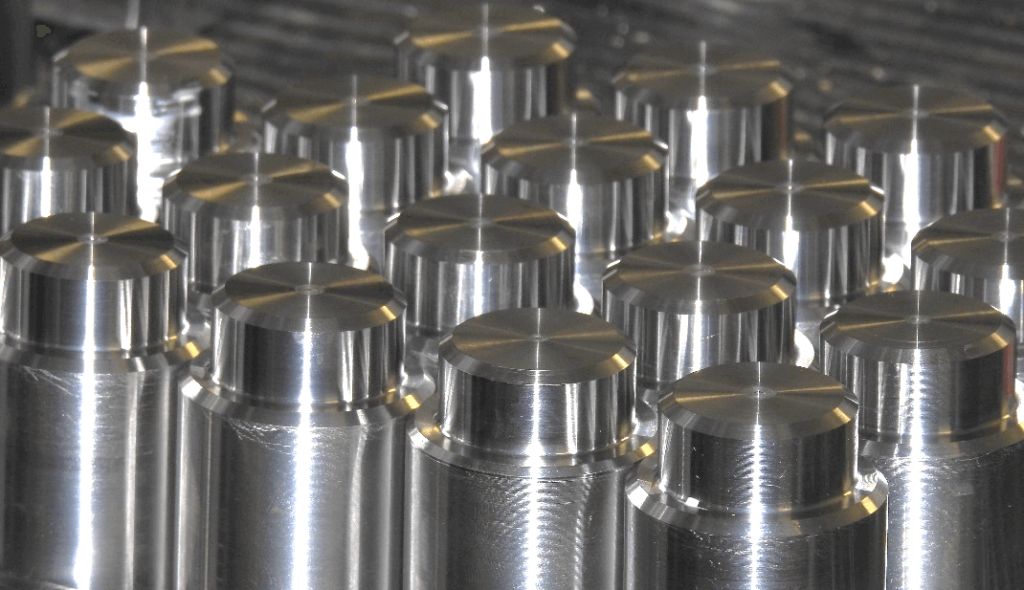

Low volume and even individual nature of production provides the ability to perform customized orders, matching up individual sets of hole-thread-screw-nut, and at the same time, modern machinery and CNC technology provides high quality of individual products. What we offer? Among others: trapezoidal threads, including high temperature threads, bolts and nuts to the hydraulic tension, studs for thermal tension, inserts and threaded sleeves, etc.