Well-made measurements – quickly, accurately, repetitively – are a necessary condition of successful project. Two things are necessary for this:

- appropriate measuring equipment;

- trained and experienced staff.

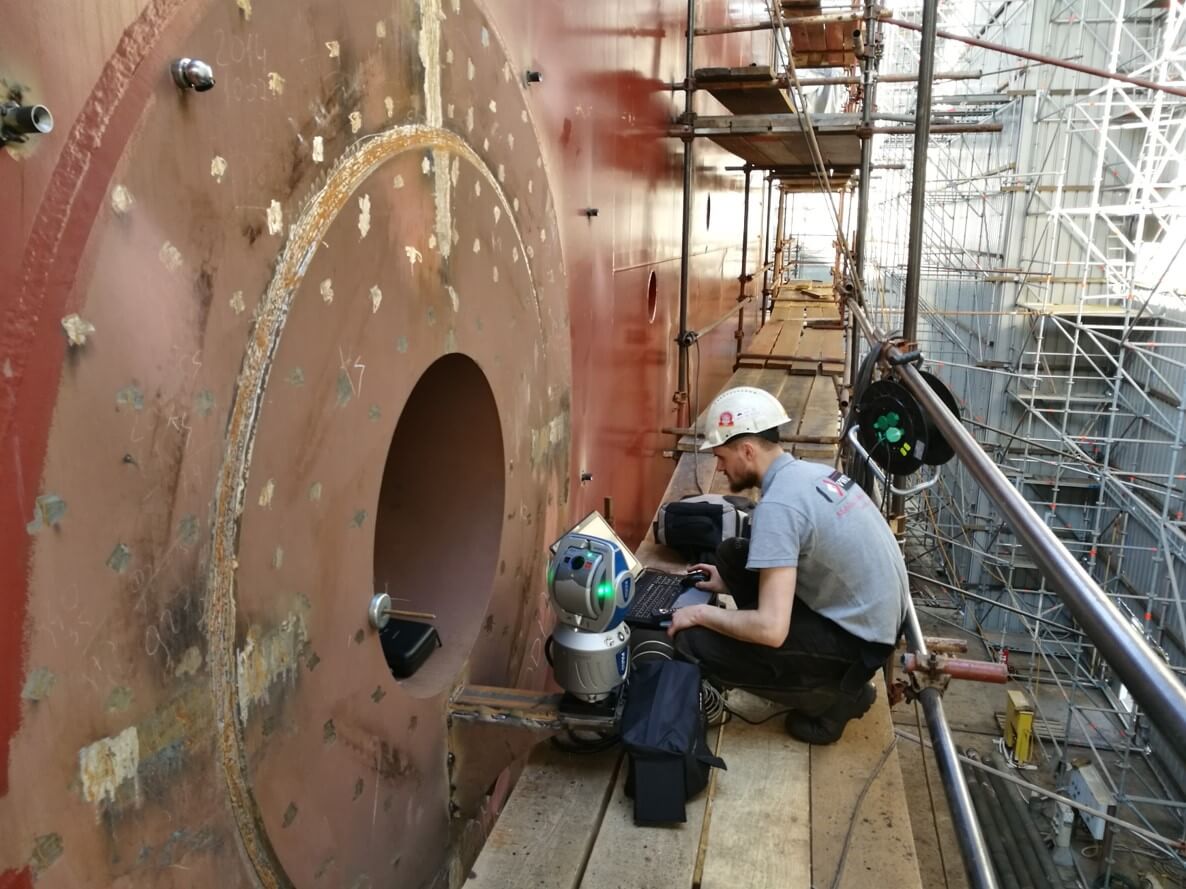

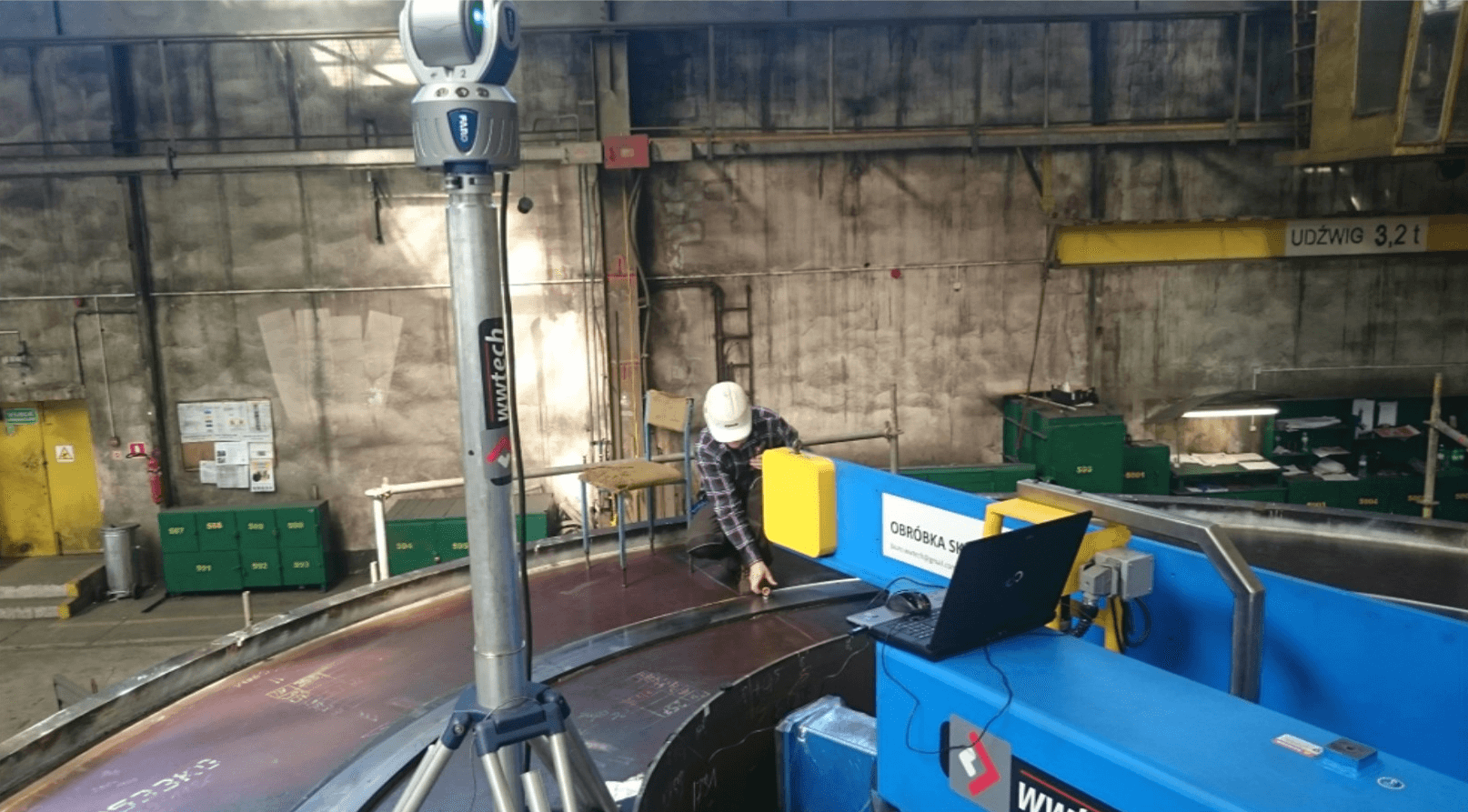

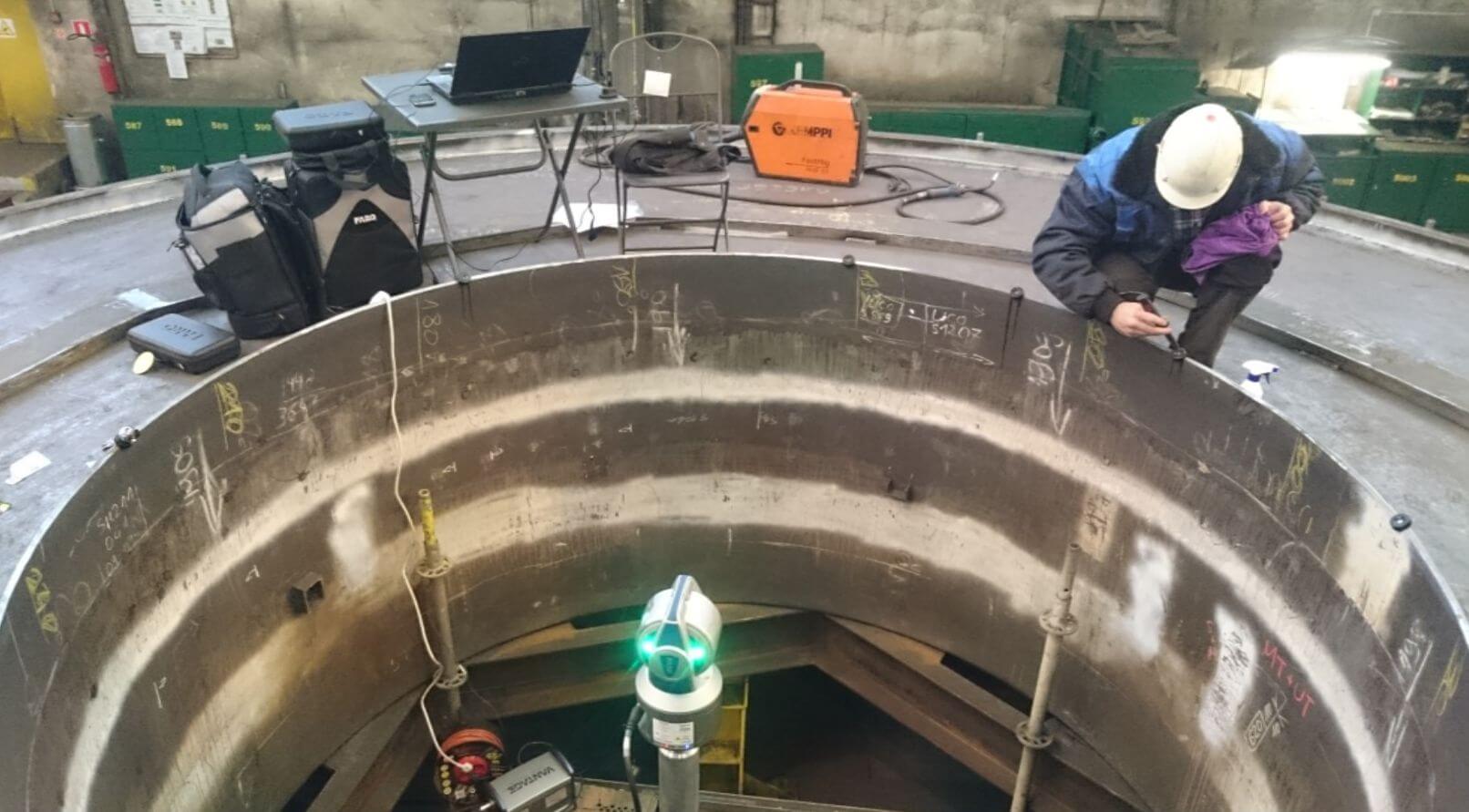

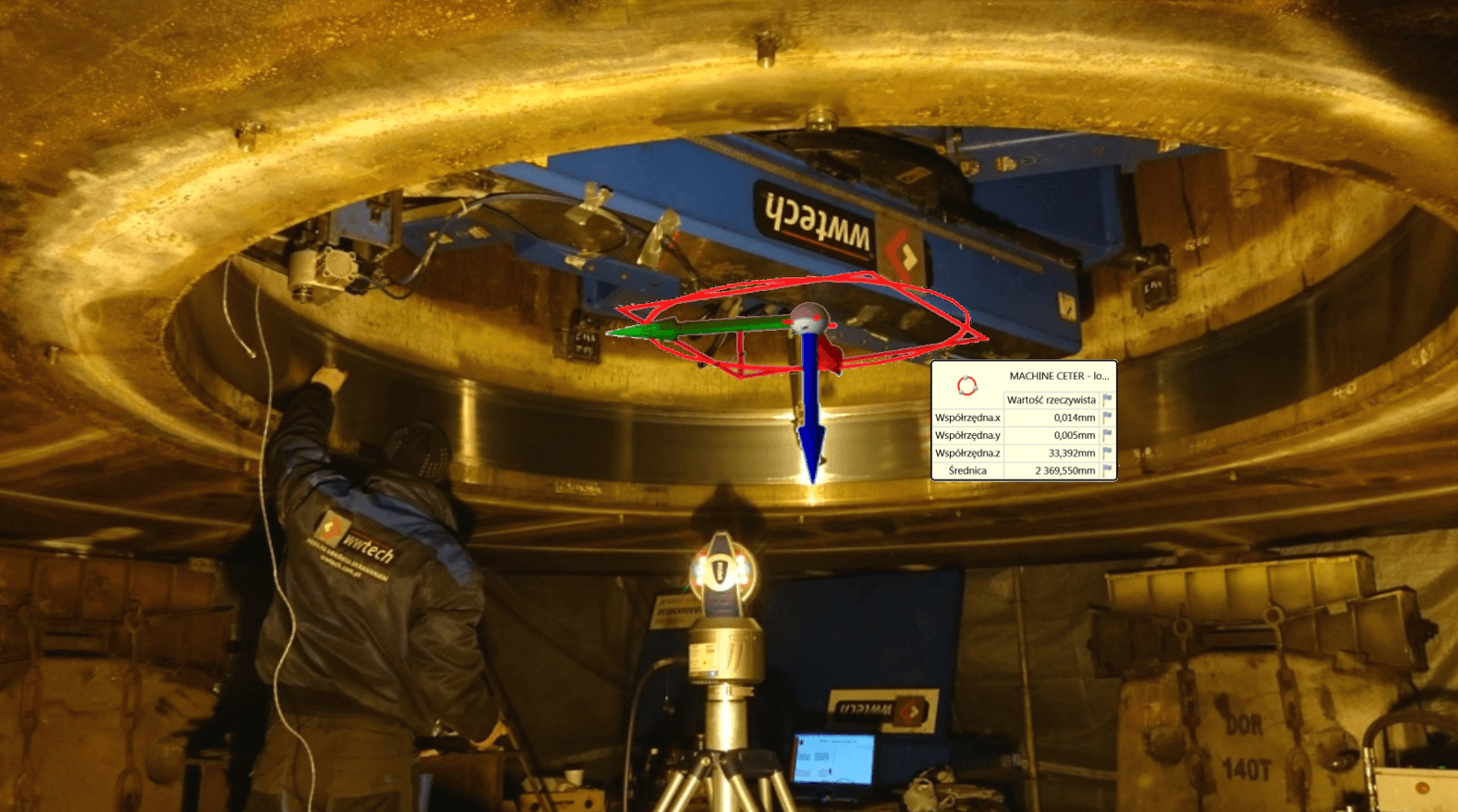

The measuring equipment must meet a number of requirements related to the nature of the work: most often there are remote measurement, resistance to humidity, dustiness and temperature changes. These requirements are met by Laser Tracker ™, which we use in our work.

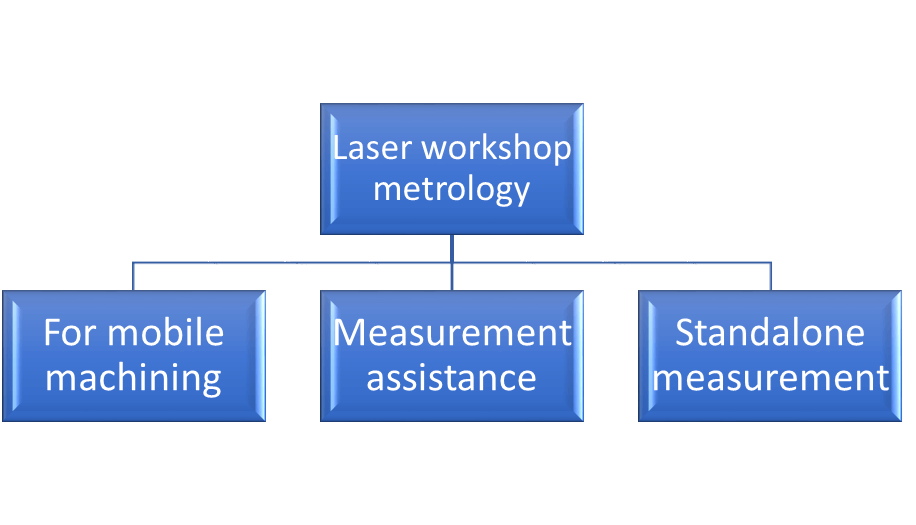

The measurements can be systematized as follows:

- For the needs of mobile machining:

- Before machining: initial dimensions and dimensional analysis – determination of allowances, determination of axes and theoretical points, marking out;

- During machining: dimensional inspection, necessary adjustments, forecasting of work progress;

- After processing: final dimensions, reporting;

- Metrological assistance:

- The service consists in performing measurements for disassembly and assembly works, including mobile machining;

- Assistance may cover the whole period of activities on the site;

- The result is ad hoc reports and recommendations as well as a final report.

- Standalone measurement:

- Standalone measurement of indicated dimensions, which results in a measurement report or geometry mapping of the object in the form of a CAD model.

More about this subject on our website: https://wwtech.com.pl/en/metrology/

Pomiary można też zobaczyć w naszym filmie:

Examples of laser measurements, recently performed for the needs of large-size machining: