Dear Visitors, Older articles from the News section are available through the main menu – the News tab; I invite you to browse.

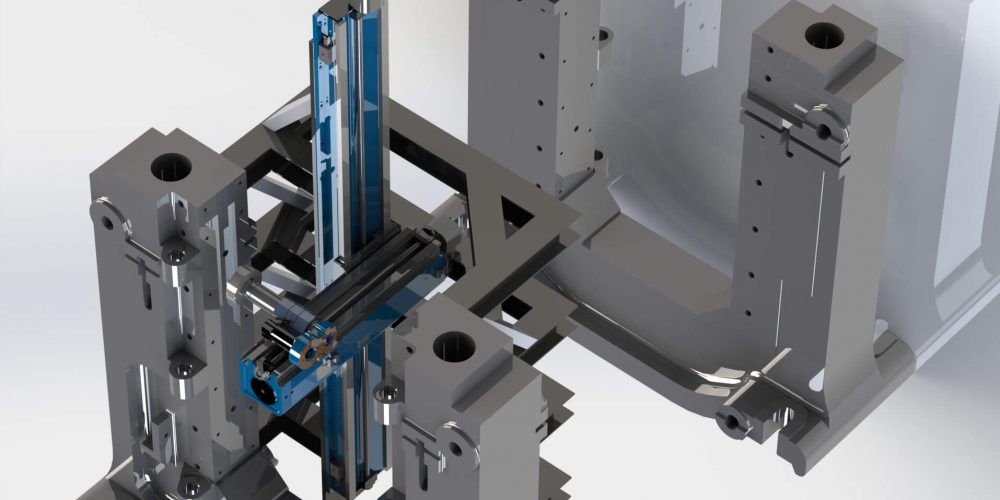

Where the scope is very non-standard, where the complex geometry of the object limits the freedom of machining using standard machines, there is a need to check the possibility of installing our equipment and then the possibility of machining. Due to this, we support us by 3D CAD technology, knowledge and software enabling the reproduction of an object and a machine in space, which allows, for example, the selection of a suitable machine, analysis of assembly options, control of possible collisions and even the design of a new machine matching the structure being machined. The latter case is not uncommon in the iron and steel industry and in hydro-power business. However, to be able to perform such simulations, we must start by making or selecting previously made 3D models. We currently have a faithful 3D representation of all our machines. The geometry of the object is a bigger problem – here a suitable 3D model is often used or the classic documentation is provided by the customer. […]

Two hydraulic presses, one with horizontal axis and the other vertical. In both cases, we have milled the surfaces of the press tables. These two examples show that mobile machines can work in any position: horizontally, vertically or inverted. In the first case, the Laser Tracker ™ was also used to determine the machining geometry. In the second case, this was not necessary, as the task was a facing of the surface due to high post-operational wear

The tiny Angaback hydroelectric power plant, belonging to the Scandinavian giant Statkraft and the Polish large hydropower plant PGE Dychów. Very similar work involving the machining of a groove for sealing of vanes. However, the main difference is the diameter of the flow path of the water turbine. For this reason, we used different machines to achieve the same goal in both cases. Angaback Dychów Output [MW] 7 90 Commisioning 1952 1936 Damming [m] 7 18 Type Flow Pumped storage Number and type of turbines 2 x Kaplan 3 x Kaplan Machining diameter [mm] 4000 5000 Machine tool FF8200 CM6200 Type of machining Turning Circumferential milling

It is worth to know that WWtech also produces piston rings. Only at first glance it is easy. However, thanks to our experienced staff and appropriate equipment, we can now offer large diameter piston rings. Application: all types of servomotors and hydraulic cylinders as well as combustion engines.

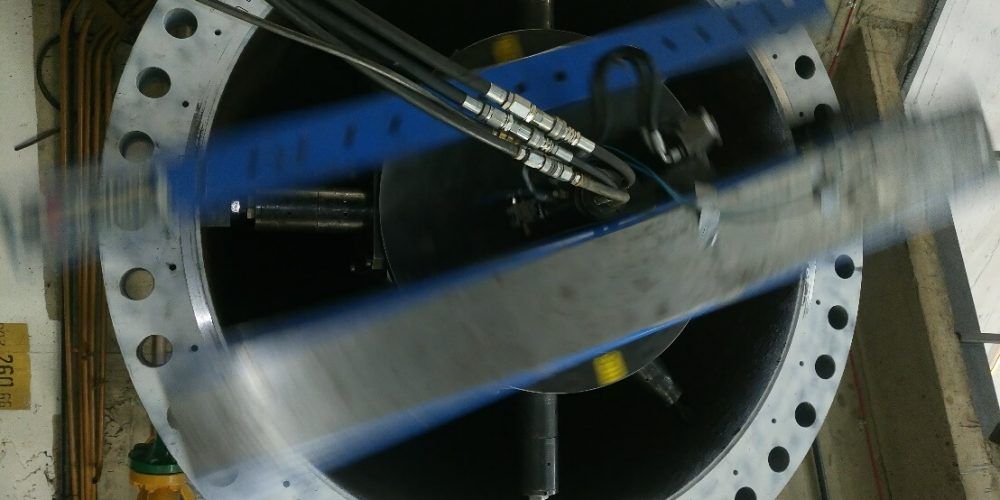

This time, the only underground hydroelectric power plant in Poland, operated by PGE. The scope of work typical for our company: machining flanges from large diameters.