The main aspects of turning surfaces of cylindrical drums, shafts and journals are:

- a wide range of rolling element dimensions (diameters from several dozen millimetres to over one-meter, turning length – narrow strip or several hundred millimetres);

- often limitation of the machine installation location resulting from the design of the device;

- high requirements for surface quality and shape deviations;

- heterogeneous surface hardness in the machining area (this phenomenon often occurs on renovated bearing journals).

Most often, the turning task requires the adaptation of a standard machine or the design of a dedicated solution.

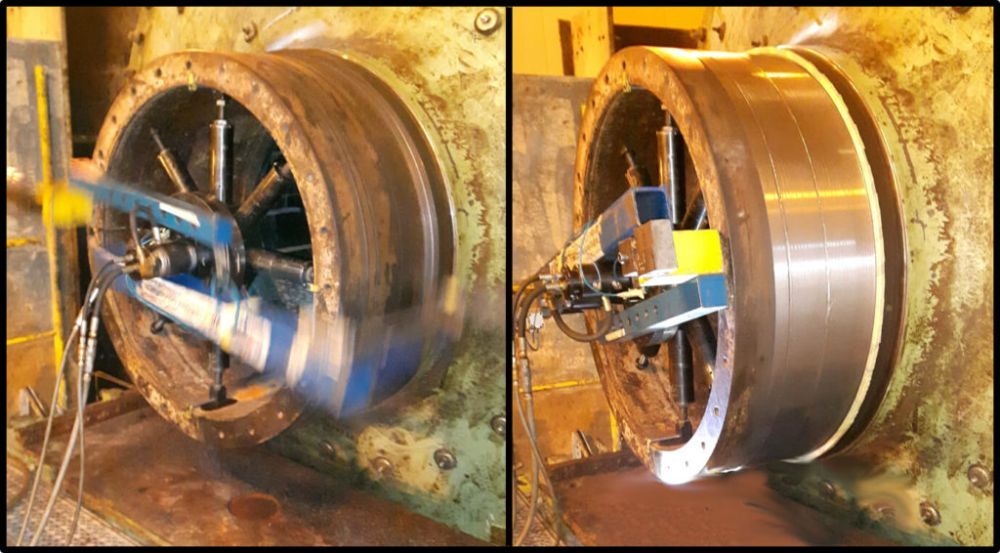

Case 1: large diameter, forehead access.

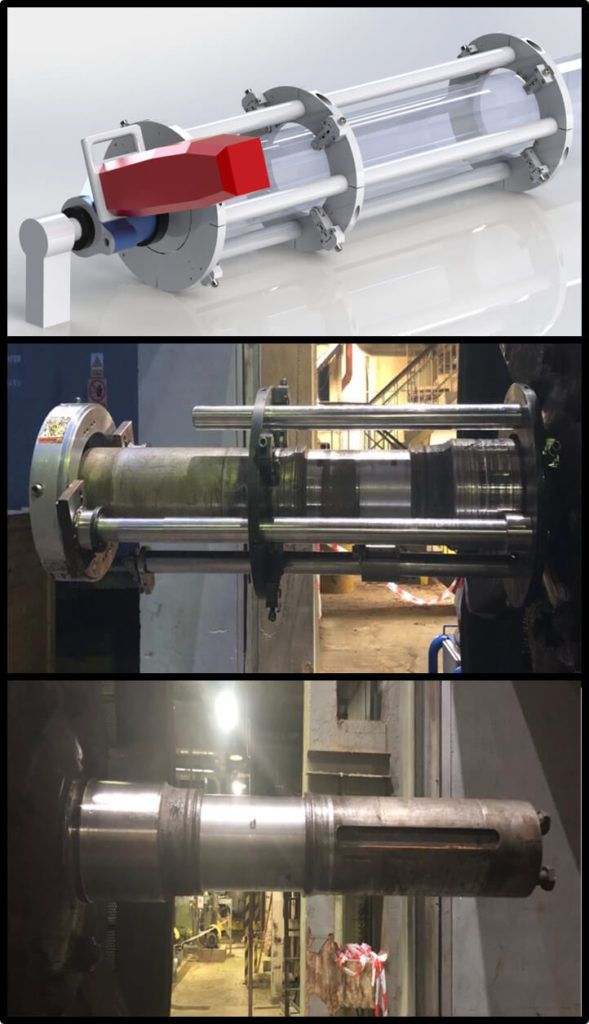

Case 2: large turning length, stepped shaft, high demands on the concentricity of the turned surfaces.

A special machine tool has been designed for this purpose, giving the possibility of turning over a large length, taking into account the change in turning diameter while maintaining the original axis.

The pictures shows: machine tool design for simulation, machining being processed, shaft finished.

Case 3: large diameter.

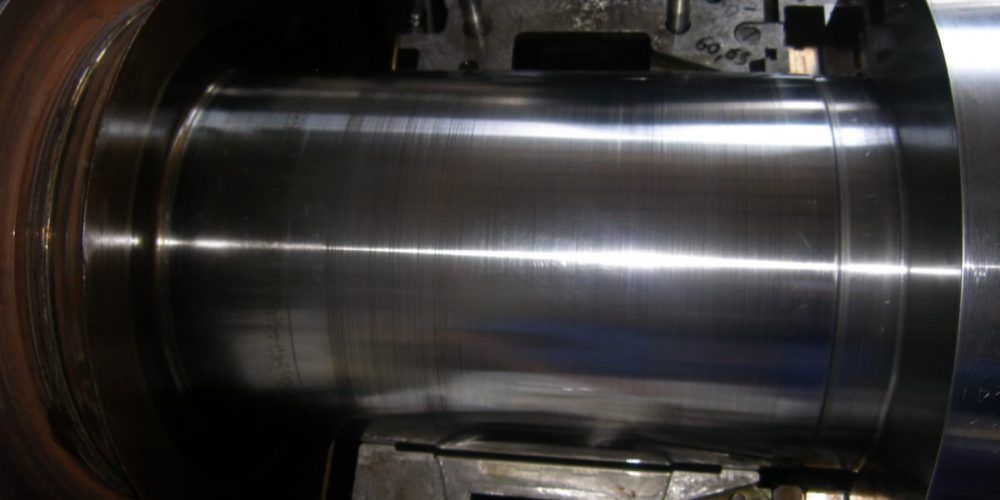

This time, a water turbine shaft with a diameter of 1150 mm, processing length 815 mm. Therefore, a machine tool of appropriate dimensions was designed with a stiffness that allows obtaining very low roughness at the level of Ra 0.3.

Case 4: shaft turning in a niche.

In this case, the key limitation was the lack of direct access to the processing site.

A short video of this task: