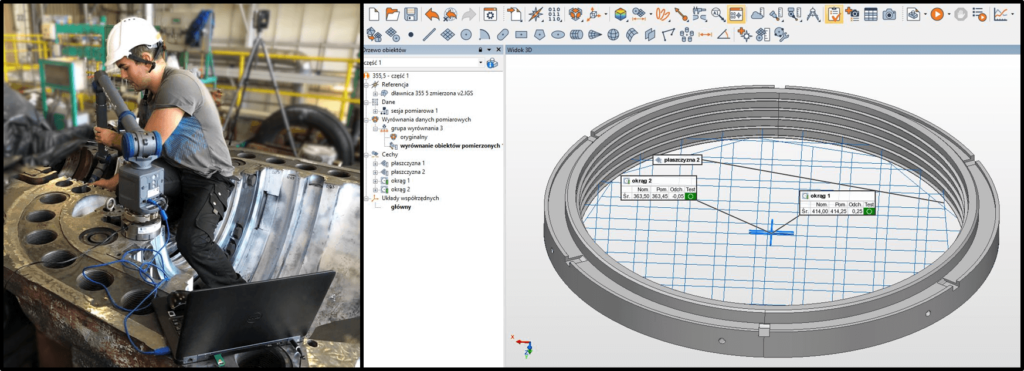

This time we present the FAROARM ™ QUANTUM measuring arm and its applications.

The arm allows to measure of length and angle as well as deviations in shape and mutual position, both for material and abstract objects – such as, for example, axes of holes, theoretical shape, etc.

The most common applications are:

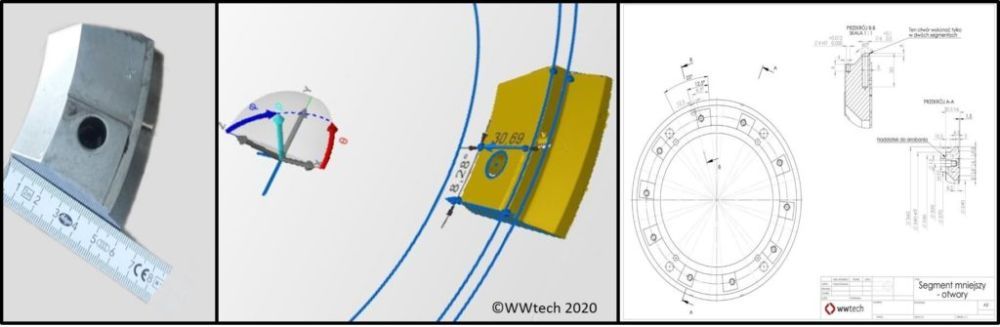

– Reverse engineering, (“back engineering”, “reverse designing”) – reproduction of the geometry of the measured object in order to prepare (dimensioning) a computer model of the object geometry and technical drawings. (Example 1)

– Dimensional check of cooperating elements to match with newly manufactured spare parts.

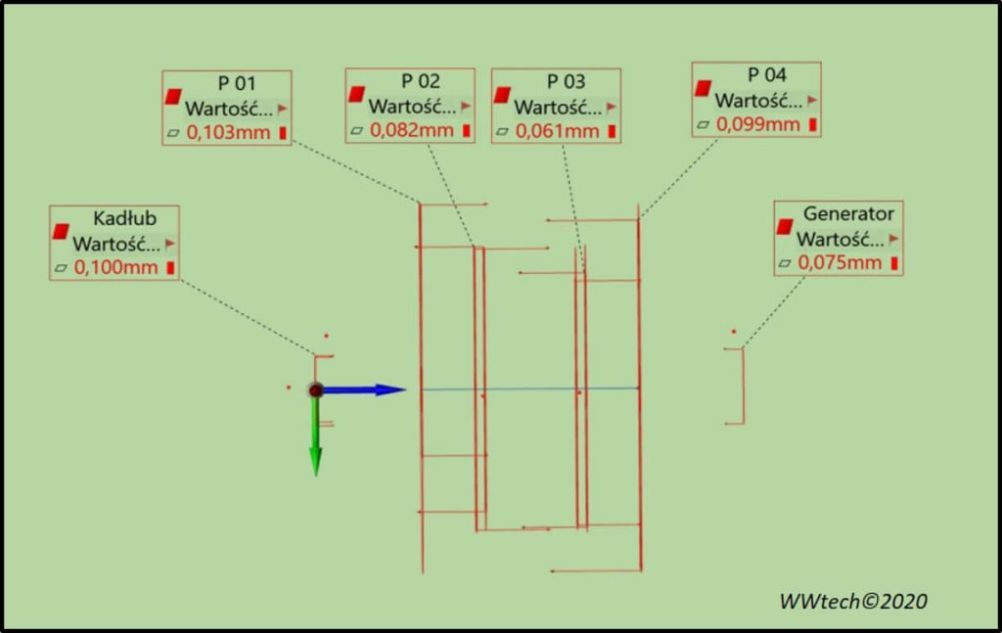

– Dimensional check of production (inter-operational, final). The measuring arm then acts as a universal measuring instrument. (Example 3)

– Measurements not yet possible to be carried out directly, e.g. mutual position of the hole axes, parallelism of the planes, concentricity of the holes, etc. (Example 4)

Example 1: Measurement of a dismantled element to prepare design documentation.

Example 2: Modelling of the cooperating element (gland body).

Example 3: Dimensional check of the ready product, including measurement of shape and position deviations.

Example 4: Measurement of total flatness and mutual position of planes.

The measuring arm shown at the pictures allows for measuring with an accuracy of approx. 0.018 mm over a measuring length of 2.4 m. This value is comparable to the stationary CMM (Coordinate Measurement Machine).

The arm length does not limit the measuring possibilities. By using base point measurement, the entire arm can be moved to a new position, thereby increasing its range.

It works perfectly in cooperation with the Laser Tracker ™, which has a dedicated measuring arm positioning function.

More about the Laser Tracker ™: https://wwtech.com.pl/en/2019/03/18/the-workshop-metrology/

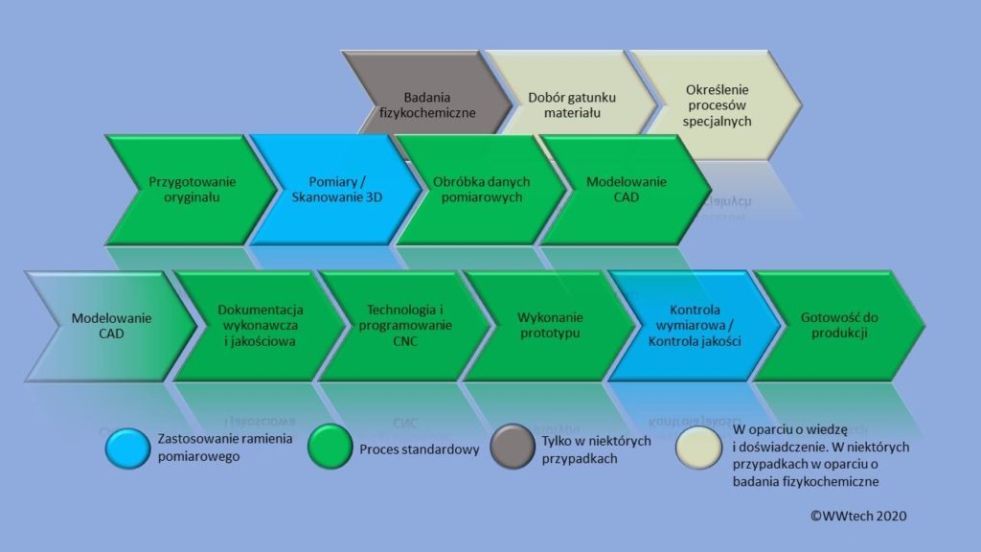

Full reverse engineering process

Reverse Engineering is common and legally acceptable way of reproducing machine components. It involves starting to use a publicly available product or set of information and disassembly, breaking it down into parts, measuring geometry and physicochemical tests (e.g. chemical composition, hardness) to discover how to recreate its design.

We generally do this to:

- change or repair the product (e.g. modernizations, renovations);

- make a compatible product (e.g. matching spare parts);

- create a competitive product (e.g. improved spare parts);

- acquire knowledge useful in other applications (e.g. testing the durability of elements from different manufacturers).

More about measuring arms:

https://www.faro.com/pl-pl/produkty/3d-manufacturing/faroarm/

Film about the shoulder Faro Quantum: