We finished the work on the modernization of the gas turbine, where our task was a.o. very difficult drilling for the casings’ retaining elements. The problem we had to face is the difficult position of drilling – on the edge between two different materials, with a step or drilling into the halve of the old hole. Since the holes were arranged around the perimeter, some of them were also drilled in the ceiling position. Drilling diagram and example of the appearance of the hole before drilling Drilling in the ceiling position The finished hole and the dowel Punching a new hole

Blurring of the thrust disc of the thrust bearing is a big problem for the owner of the device. However, such cases can be regenerated without dismantling the rotor, which is costly and time-consuming work. To this end, we have developed a device for turning and grinding thrust discs as well another face surfaces on turbine rotors, without disassembly. Local surface hardening, caused by an increase in temperature due to friction – causes of damage – are always a major obstacle that needs to be taken into account in the regeneration of the thrust disc. Usually, the requirements for surface quality and deviation of shape are very high, hence the […]

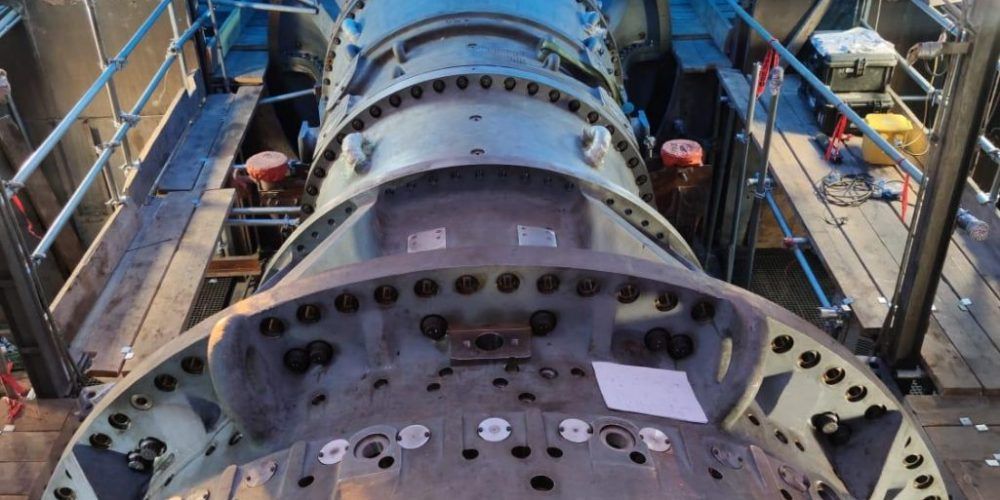

Our client has decided to modernize the screw connection of the turbine flanges. In place of the traditional connection with stud bolts crewed into the lower half of the cosing, it was decided to make through holes with a slightly larger diameter than the original solution. In the first step, due to the shape of the casting, a feasibility study had to be carried out – for this purpose, a 3D scan of the flanges was performed, with a particular focus on the radii of the transition to the casing area. The result is a three-dimensional model of the casing’s fragment within the area of planned upgrade. On the same […]

We are pleased to announce that from April 2020 we are cooperating with WENA Consulting in the field of Environment, Health and Safety, fire protection and preliminary and periodic trainings and dedicated to specific topics e.g. first aid, support of AED defibrillator, etc. More information: https://wenakonsulting.pl/

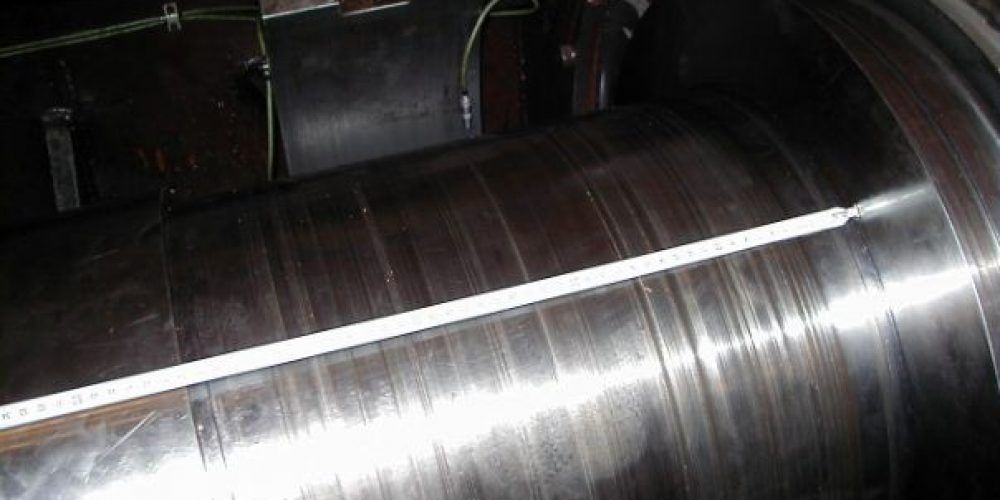

Failure of the oil system can have serious consequences. In this case, the bearing journals have been very seriously damaged. However, it is unusual that the scratches caused by the friction in the dry bearing were more than 2 mm deep. The repair consists in turning and then honing the surface of the journal. In this case, due to the depth of the scratches, it lasted several days. More about such work: https://wwtech.com.pl/en/2020/02/04/drums-shafts-and-journals-turning/

We are proud to inform you that our Company has obtained the system certificate at Occupational Safety Management ISO45001.This standard helps organizations manage processes and risks related to health and safety at work in a systematic and consistent manner. ISO 45001 replaces OHSAS 18001 (in Poland PN-N 18001), which will be discontinued on March 12, 2021. This means that by then, all organizations that currently have a valid OHSAS 18001 certification, for continuity, are required to update their system to the requirements of the new version of ISO 45001. Iso 45001 certification is a reliable proof that all processes implemented in our organization are oriented towards ensuring safe working conditions. […]

It often happens that replacing or upgrading one of the coupled devices, causes the need to regenerate the coupling holes on the “old” side. If the sloping is small, it is sufficient to jointly machine and/or honing pairs of “old” and “new” holes – so-called “pairing”. In the case of large fares, i.e. in cases of: unevenness of the axes of both holes (“spraining”) – usually arose during previous repairs, offsets of the holes’ pitch of the two semi-couplings relative to each other serious damage to the surface of the hole (deep tears, etc.), Ovalization (“’breakdowns’) approaching the limit of “repairability” of the holes due to the need to […]