It often happens that replacing or upgrading one of the coupled devices, causes the need to regenerate the coupling holes on the “old” side. If the sloping is small, it is sufficient to jointly machine and/or honing pairs of “old” and “new” holes – so-called “pairing”.

In the case of large fares, i.e. in cases of:

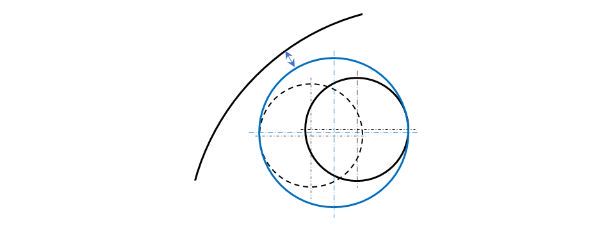

- unevenness of the axes of both holes (“spraining”) – usually arose during previous repairs,

- offsets of the holes’ pitch of the two semi-couplings relative to each other

- serious damage to the surface of the hole (deep tears, etc.),

- Ovalization (“’breakdowns’)

- approaching the limit of “repairability” of the holes due to the need to exceed the maximum permissible diameter,

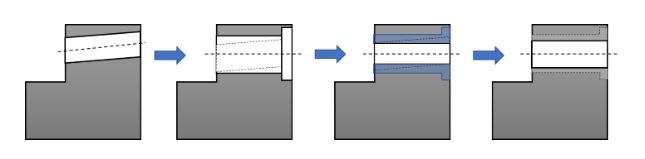

a more complex regeneration is needed to restore the original connection geometry. For this purpose, bushings are used, embedded witch shrink, in specially prepared holes.

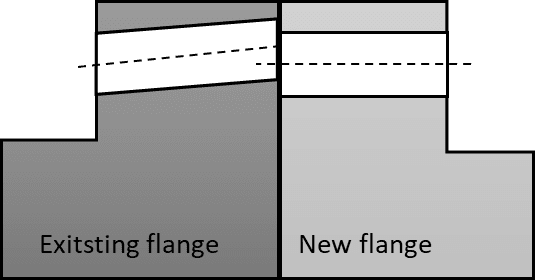

It is also important that the new hole, covering both holes, does not exceed its semi-clutch edging size.

Bushings can be made with a resistance flange or smooth, however, this depends on the nature of the load and the type of clutch screws.

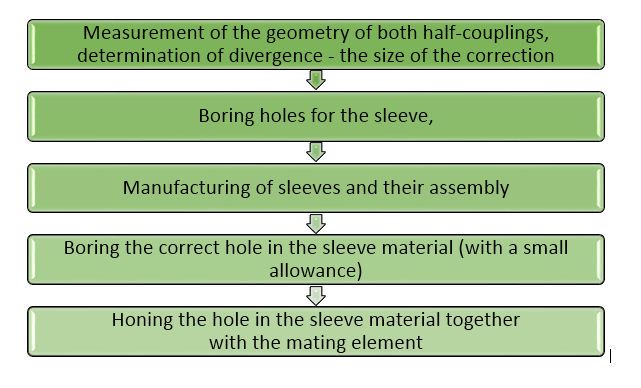

The regeneration operation can be divided into stages:

In this way, you can regenerate – restore nominal dimensions – on all coupling holes or regenerate individual holes.