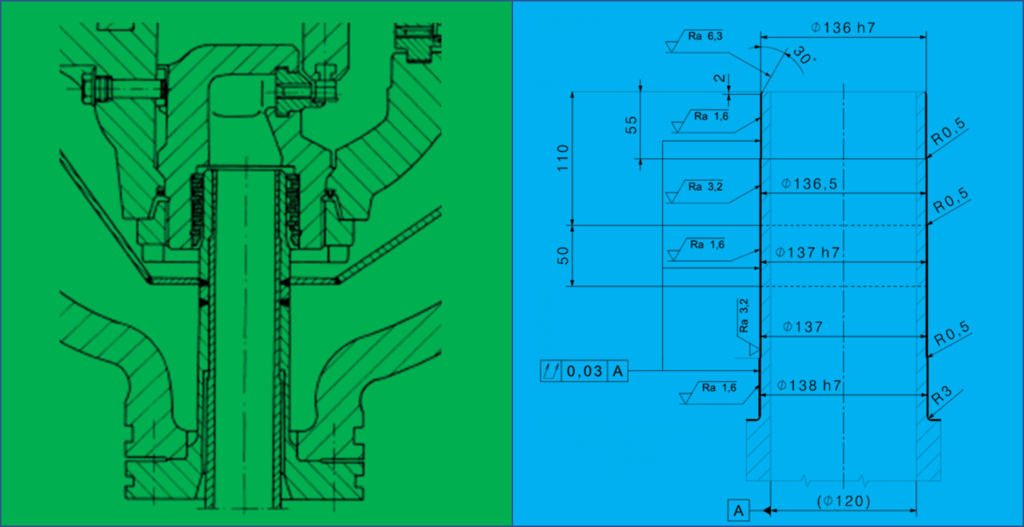

Telescopic bushings are a very important and responsible element of the steam admission system in the steam turbines due to the extreme operating conditions (even 540 °C, 20-30 MPa). The seal typically consists of a set of multi-edge seals to seal the coaxial portions of the intake pipeline. The reason for using such a solution is the possibility of installing the inner casing in the outer one, as well as compensation of thermal expansion of the elements.

This time, the task was to machine heavily worn-out sleeves to new diameters. While stationary machining of such an element is trivial, fulfilling the design requirements of machining in the mobile version, including the mutual position of the axes of two sleeves, is not the easiest task.

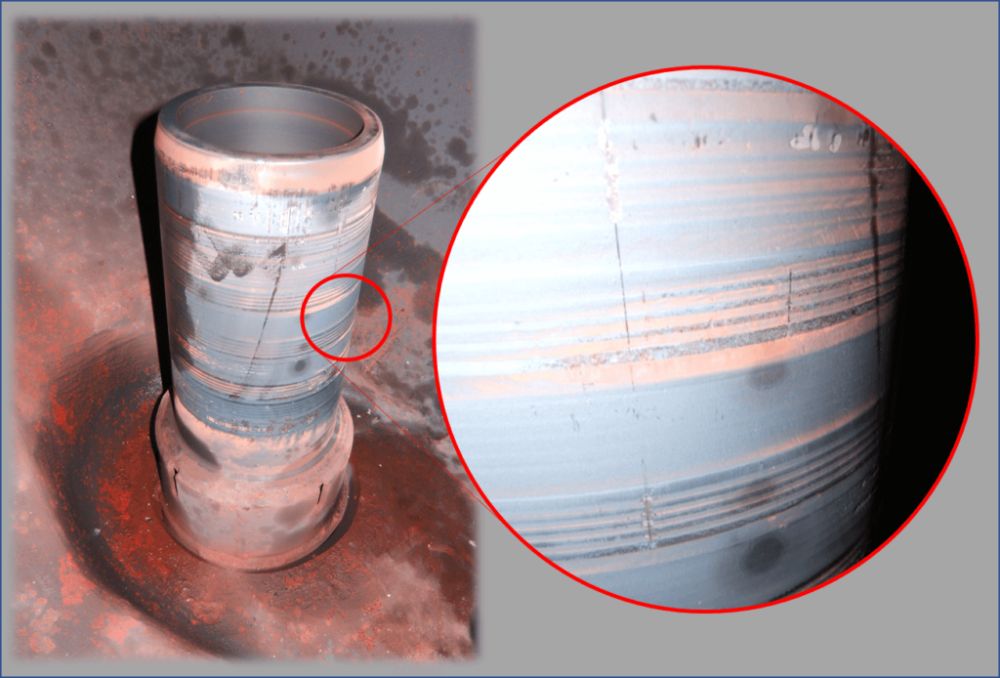

Fig. Condition before machining. Washout (depth approx. 0.5-0.7 mm), corresponding to the position of multi-edge seals.

Fig. One of the sleeves after machining.