In addition to large projects (e.g. https://wwtech.com.pl/en/2020/01/29/two-milling-machines-in-action/ ), WWtech also provides a wide range of small mobile machining services

-

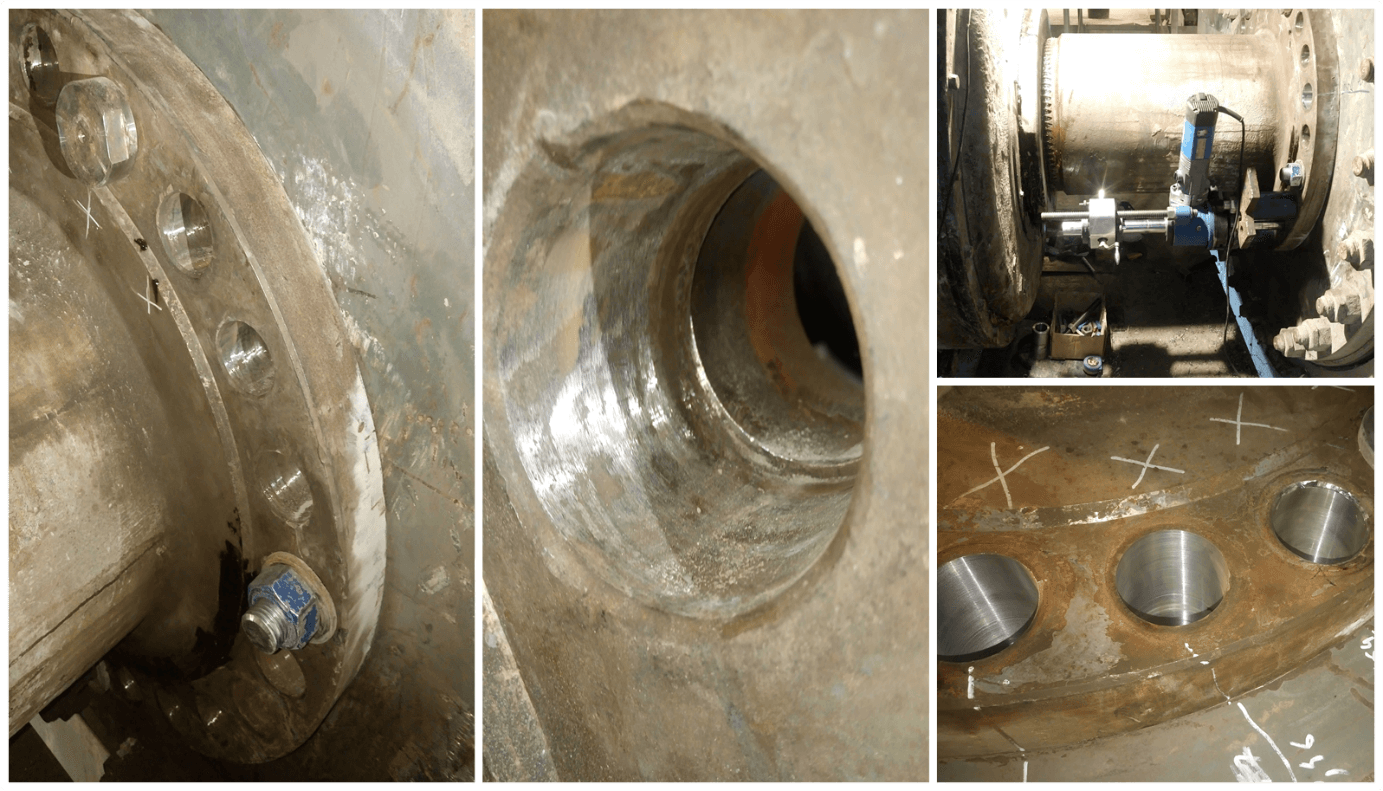

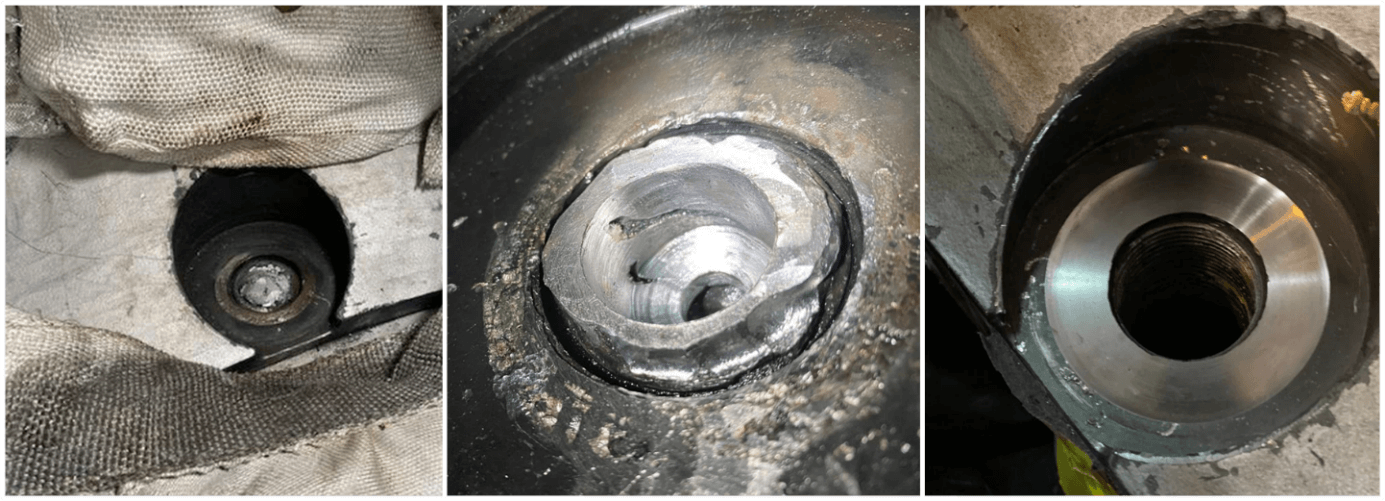

Removal of broken/seized bolts and studs, even in hard-to-reach areas. Sometimes the thread is also damaged, then we offer a number of repair techniques. Some of them were already presented in the article: https://wwtech.com.pl/en/2019/06/24/repair-of-threaded-holes-2/

The choice of the optimal m.in method depends on:

- nominal thread size,

- screw and body materials,

- reasons for breaking or blocking,

- possible deformation,

- further use of the thread (e.g. oversizing)

- access to the place

-

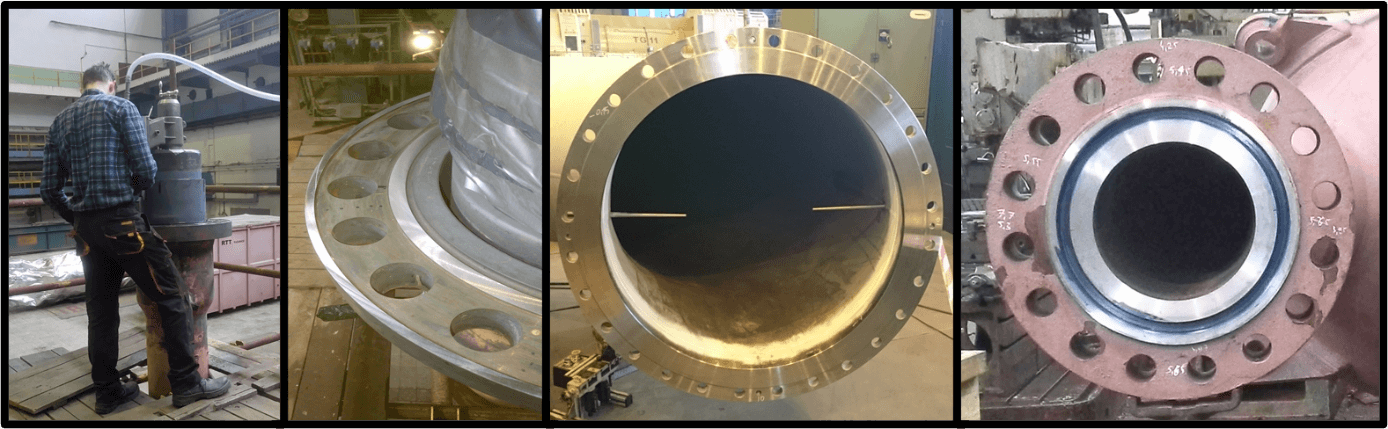

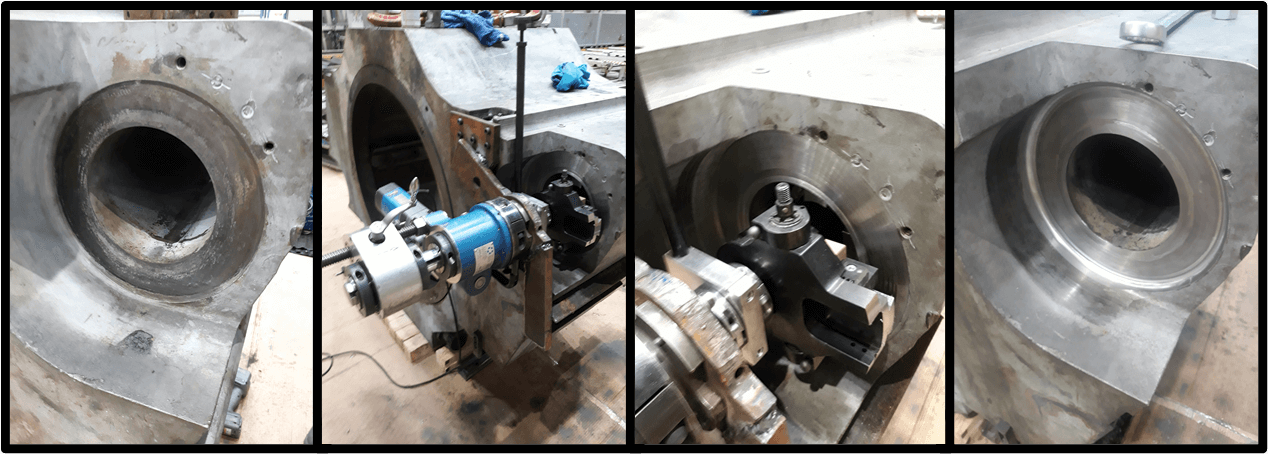

Regeneration of the groove under the sealing ring. The crushed section of the edging was restored by a weld by the Customer and our role was to machine to restore the original shape. Thus, with little effort, the functionality of a large, costly element has been restored

-

Planning – facing of sealing surfaces – flanged joints. More about the scope and equipment in the article: https://wwtech.com.pl/en/on-site-machining/boring-and-turning-using-portable-machinery/machining-of-flanges/

-

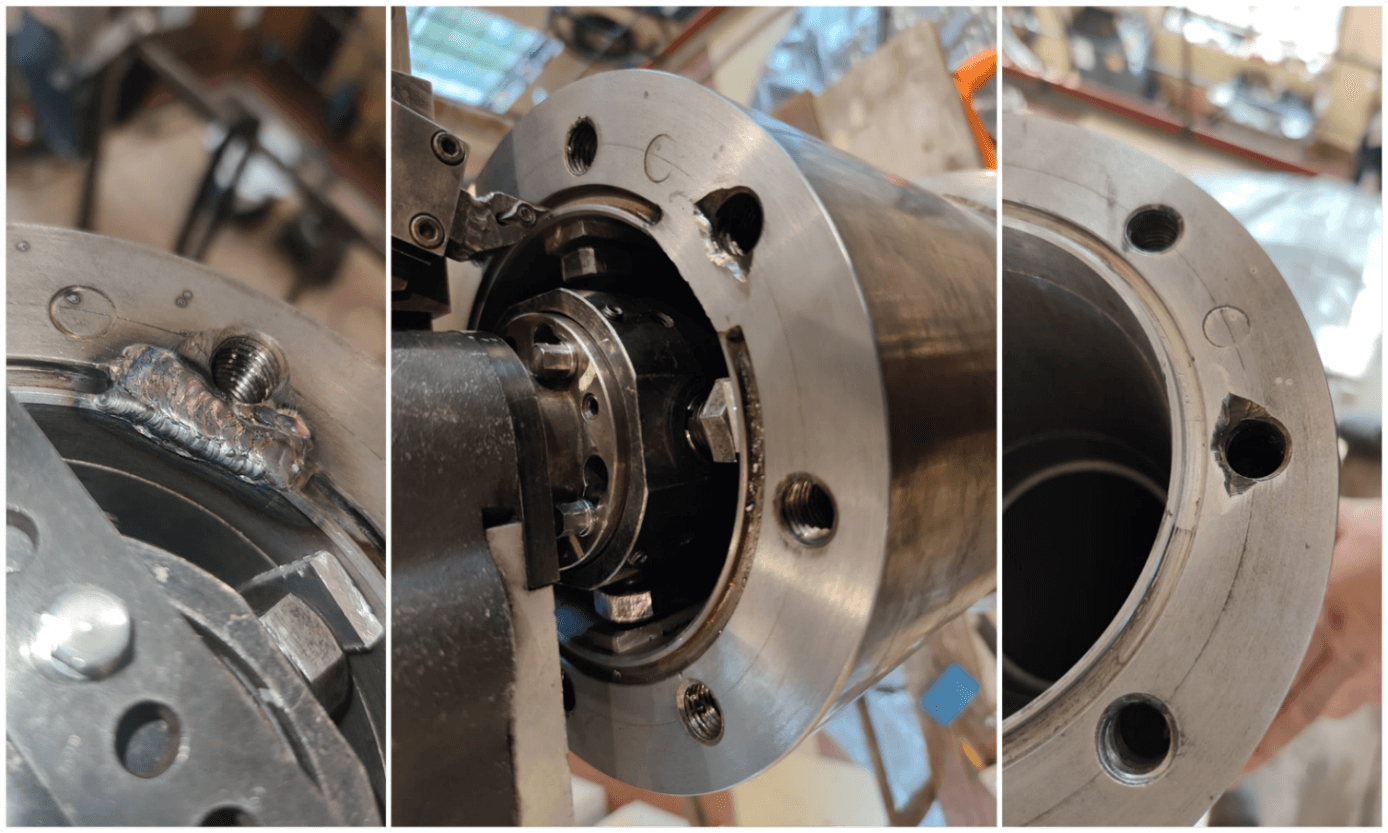

Reaming/boring out damaged holes. In addition to the expansion of the holes, we also recreate the original geometry e.g. https://wwtech.com.pl/en/2020/10/14/regeneration-of-coupling-holes/ and https://wwtech.com.pl/en/on-site-machining/drilling-and-reaming/