Kayrakkum Dam (Russian: Кайраккумская ГЭС; Tajik: НБО Қайроққум), also spelled differently as Kayrakum, Kairakum, Qayraqqum or Qayroqqum, is a dam on the Syr Darya River near the city of Kayrakkum in Sughd Province, Tajikistan. It is located on the western edge of the Fergana Basin and forms the Kayrakkum Reservoir. The reservoir supplies water for irrigation, mainly in Uzbekistan in the lower reaches of the river, and for the production of hydropower. The power plant has an installed capacity of 126 MW and is operated by the state-owned operator Barki Tojik. Construction of the dam began in 1952. Six units with Kaplan turbines were commissioned in 1956 and 1957. The power plant is currently undergoing modernization and renovation, aimed at increasing the power plant’s capacity from 142 to 174 MW. At the invitation of GE, the supplier of new turbosets, we perform machining on subsequent six blocks. We have just finished work on unit 5, the second of six being machined by ours. There are four more blocks ahead of us. In the scope of machinig: machining of the upper and lower ring, faces and cyllindrical surfaces, […]

Bujagali Power Plant is a hydroelectric power plant on the Victoria Nile, a place considered the beginning of the great Nile River – near the beautiful Bujagali Falls in Uganda. Construction began in 2007 and was completed in 2012. The power plant has a capacity of 250 megawatts. The Bujagali Power Plant was uganda’s largest source of energy when it was commissioned. GE supplied all electromechanical equipment – including five Kaplan turbine-generator units with a capacity of 50 MW each, control and protection systems and other power plant equipment. GE’s Kaplan turbines feature adjustable rotor blades and adjustable steering blades that enable them to efficiently deliver power over a wide range of flows, where river flows vary greatly depending on the season. More about power plant equipment: Bujagali – Flawless project execution | GE Renewable Energy About the Bujagali hydropower project – AKDN This time, at the invitation of GE, we performed […]

Borgforsen is a small 26MW hydroelectric power plant on the Fjällsjöälven River in central Sweden, equipped with Kaplan turbines. Two tasks: line boring of holes for guide Vvanes turning the spherical part of the rotor chamber. Insofar as reaming is a standard activity and performed by us many times, the turning of the spherical part was for the first time made with a new machine of our own construction.

Rana Power Plant is located near the town of Mo I Rana, in central Norway . It operates with installed capacity of 500 MW in four units with Francis turbines, with an average annual production of about 2100 GWh. The station is owned by Statkraft. In terms of annual production in Norway, the Rana power plant is second to the Svartisen hydroelectric power plant. Photo: Rana Power Plant outside and inside In our range there was machining of axuial, radial and conical surfaces within the head coverthe bottom ring. A certain challenge was to turn the over five-ton machine by 180° without access to the crane – only with the help of hoists. This operation can be seen in the video:

Nalubaale Power Station, formerly known as Owen Falls Dam, is a hydroelectric power station across the White Nile near to its source at Lake Victoria in Jinja district. Its Location coordinates are: Latitude= 0.443525, Longitude= 33.1847 respectively. It is the oldest hydropower station in Uganda commissioned in 1954. It was renamed Nalubaale by H.E Excellency Yoweri Kaguta Museveni, the president of Uganda in 2001. Originally Owen falls dam was designed for ten turbines rated at 15 megawatts (20,000 hp) each (a total of 150 megawatts (200,000 hp). In the the 1990s, the station was refurbished to repair the accumulated wear from a decade of civil disorder. During the repairs, the […]

Due to the erosion and corrosion wear of the old blades, the customer decided to replace them. For this purpose, we made a number of 3D laser measurements and scans to redesign the casting as well as the finished machining. The individual stages are presented in the diagram: In the same way, the steering vanes were recreated. More about reverse engineering: MEASUREMENT TECHNIQUE AND REVERSE ENGINEERING | WWTECH – On site machining

We invite you to familiarize yourself with the new folder, showing the activities of WWtech in a cross-sectional way. To download please click [here]

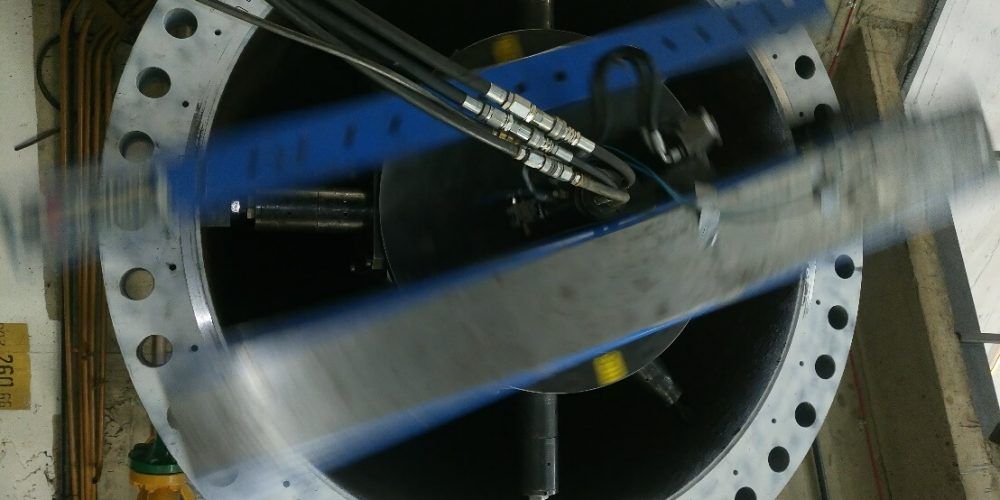

A small power plant with two Kaplan turbines with a total capacity of 18MW. The current modernization will allow for an additional 1 MW/ unit. In our scope a.o. the machining of the runner chamber. More: Our Hydro Services | WWTECH – On site machining For machining all flat, cylindrical, toroidal and spherical surfaces, we used the KWW525 machine tool. Read more: The Machines | WWTECH – On site machining Note: This photo is composed of two photographs. This is the only way to show the whole machine tool.

The tiny Angaback hydroelectric power plant, belonging to the Scandinavian giant Statkraft and the Polish large hydropower plant PGE Dychów. Very similar work involving the machining of a groove for sealing of vanes. However, the main difference is the diameter of the flow path of the water turbine. For this reason, we used different machines to achieve the same goal in both cases. Angaback Dychów Output [MW] 7 90 Commisioning 1952 1936 Damming [m] 7 18 Type Flow Pumped storage Number and type of turbines 2 x Kaplan 3 x Kaplan Machining diameter [mm] 4000 5000 Machine tool FF8200 CM6200 Type of machining Turning Circumferential milling

This time, the only underground hydroelectric power plant in Poland, operated by PGE. The scope of work typical for our company: machining flanges from large diameters.