The Machines

Among the machines we have, several types are ideal for hydro-power applications.

Facing/milling machine for flanges FF8200

- – facing capability (fi 762 – 3048mm)

- – pneumatic feed, adjustable to achieve adequate roughness

- – possibility of mounting the milling head

- – two-way guide

- – 8 adjustable legs

- – high-performance hydraulic drive

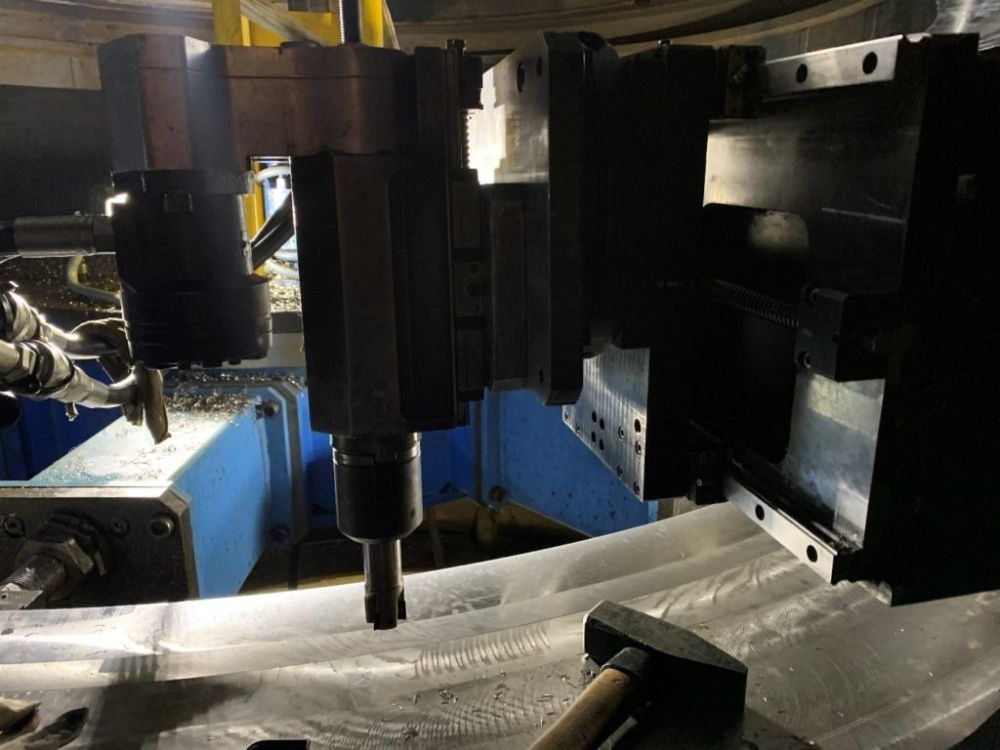

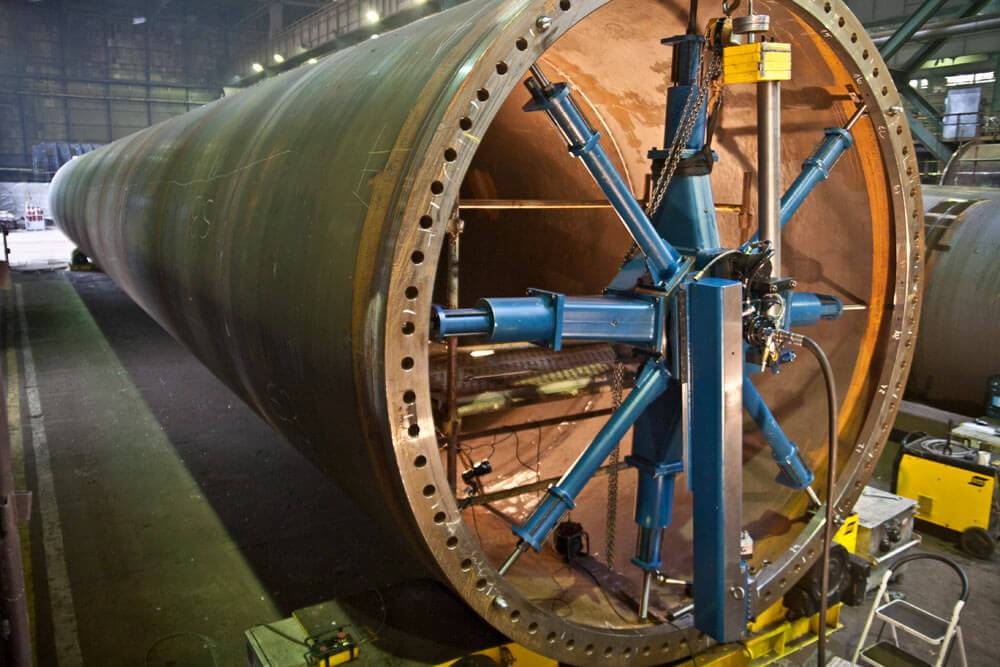

Circumferential milling machine CM6200

https://wwtech.com.pl/wp-content/uploads/2016/11/katalog-kolowa-frezarka-przenosna-climax-CM6200.pdf

- – facing capability (fi 2000 – 8500mm)

- – 8-leg mounting system (4 for leveling the entire machine)

- – milling and turning capability

- – servo system together with encoder allows precise rotation of the machine

- – high-performance ISO50 milling head

- – possibility of tilting the machine arm

- – can be mounted to the face of the workpiece surface

More photos: https://wwtech.com.pl/2020/01/29/dwie-frezarki-w-akcji/

Boring machines BB6000 and BB7100

https://wwtech.com.pl/wp-content/uploads/2016/11/katalog-przenosna-wytaczarka-climax-bb6000.pdf

https://wwtech.com.pl/wp-content/uploads/2016/11/katalog-przenosna-wytaczarka-climax-bb7000.pdf

- – boring diameters: 152 – 1069mm (BB6000) and 260 – 1480mm (BB7000)

- – possibility of using a facing head

- – modular design for quick installation

- – relative small dimensions of a machine with a power comparable to a stationary machine

- – spindle length 1400mm, 2400mm, 3000mm, 3600mm

- – maximum stroke to spindle length

- – hydraulic drive

- – manual or electric feed

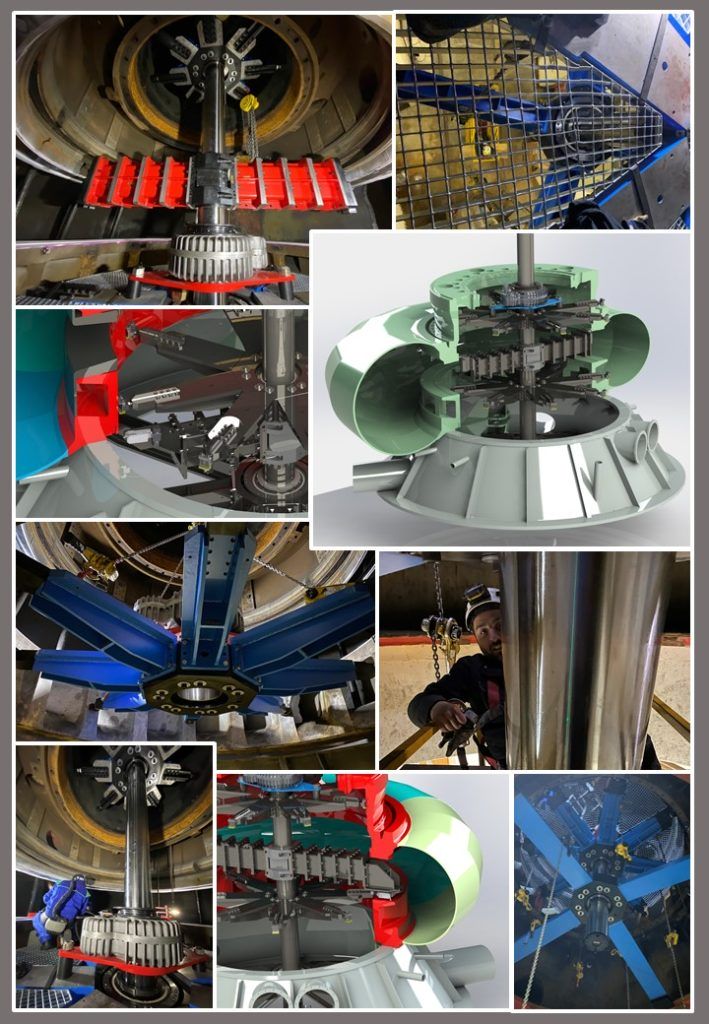

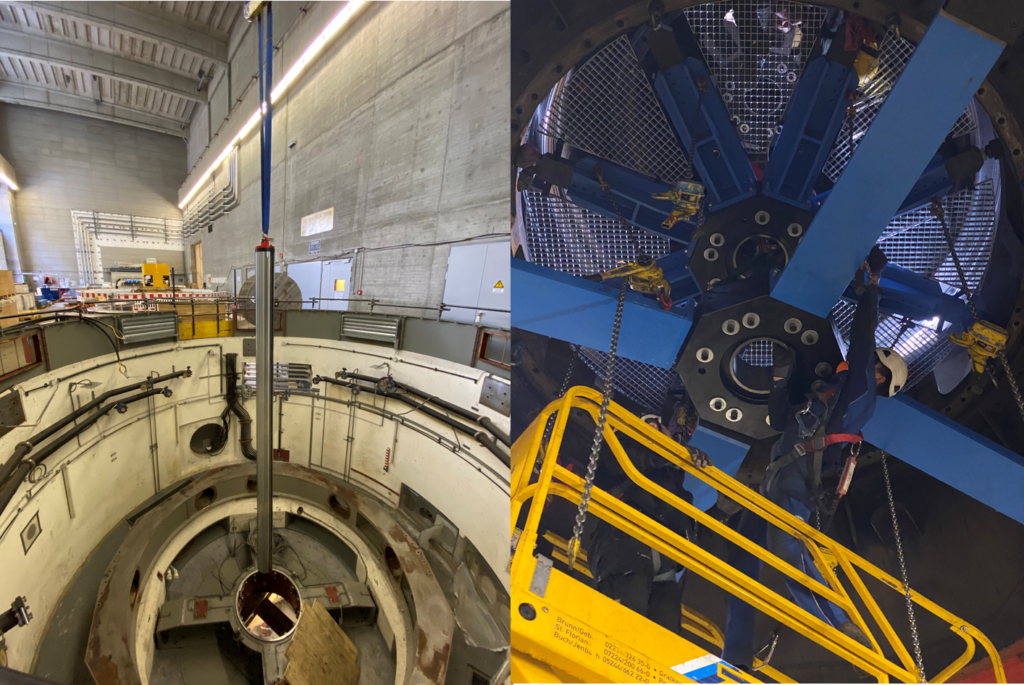

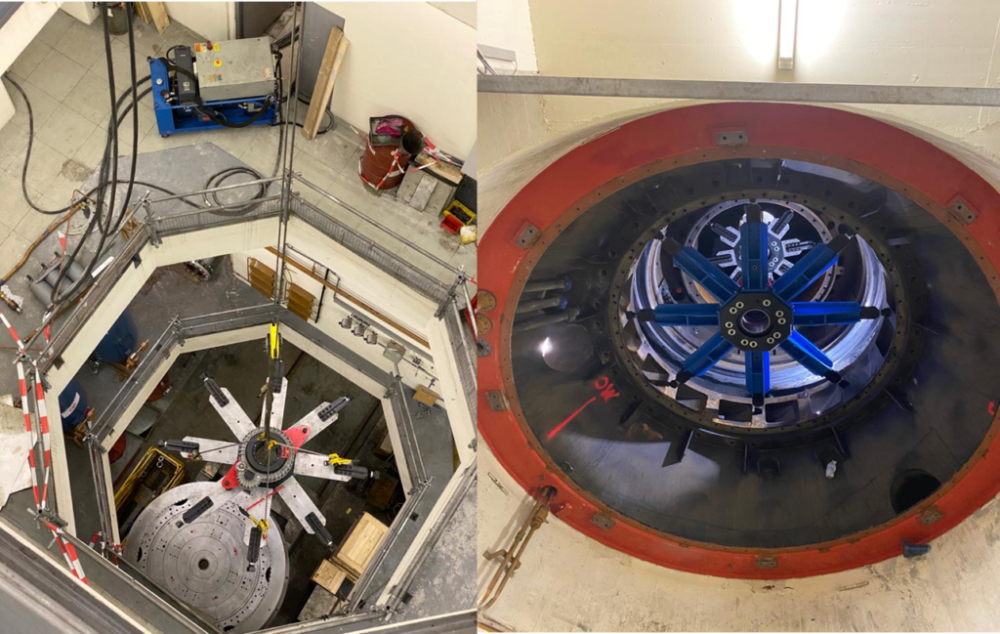

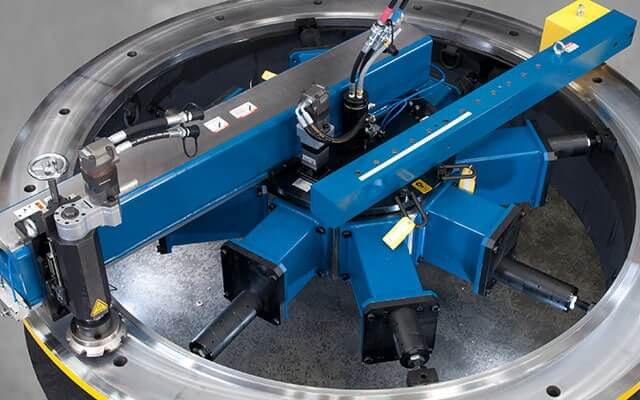

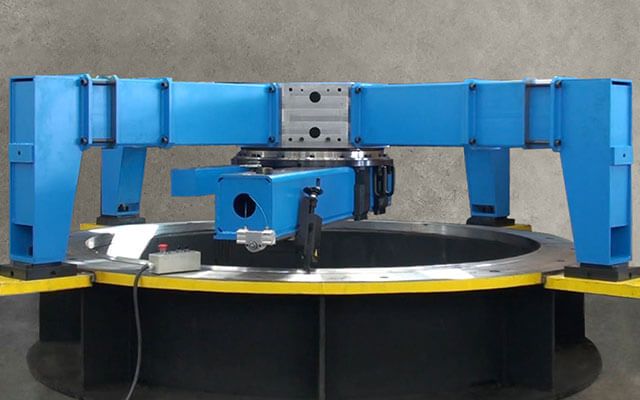

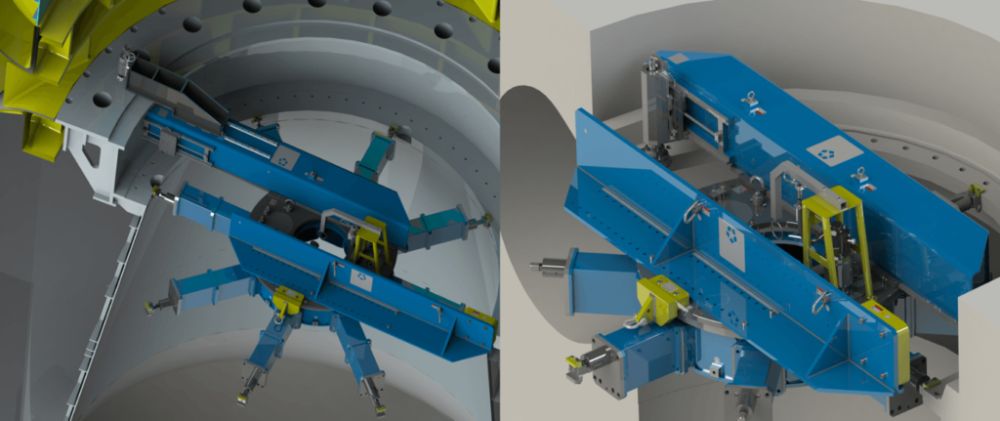

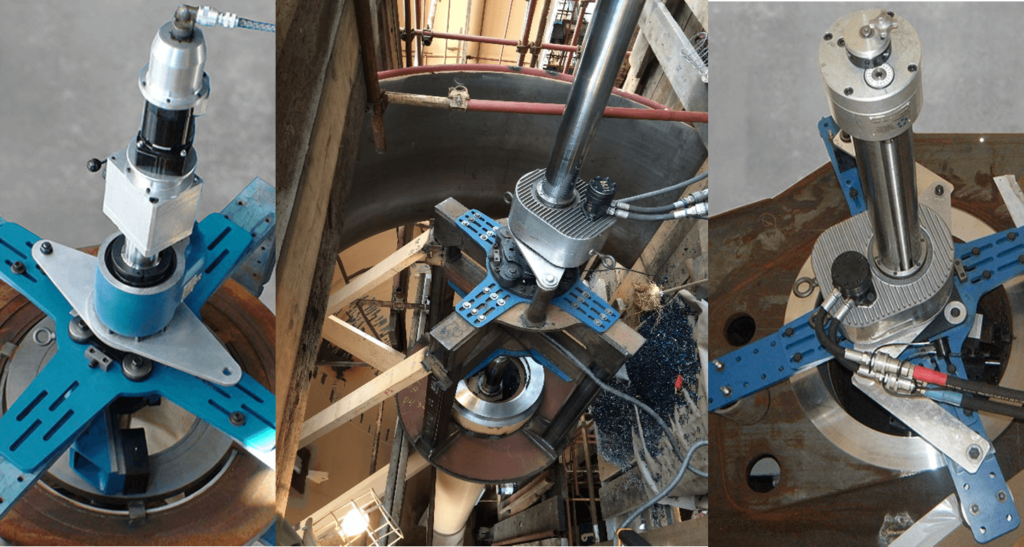

Multipurpose machine KWW525

WWtech has a machine tool that allows all turning and milling operations within the rotor chamber in a single attachment. The our own machining head design solution allows to achieve any shape of the workpiece surface, including spherical and toroid, while maintaining the required accuracy and roughness. In addition, other stationary components of the turbine can be machined in the same clamping system: the upper ring, the lower ring, the thrust bearing and even the generator. The modular design allows the machine to scale freely.