WWTECH was done the machining of the key surfaces in steam turbine’s cut-off valves.

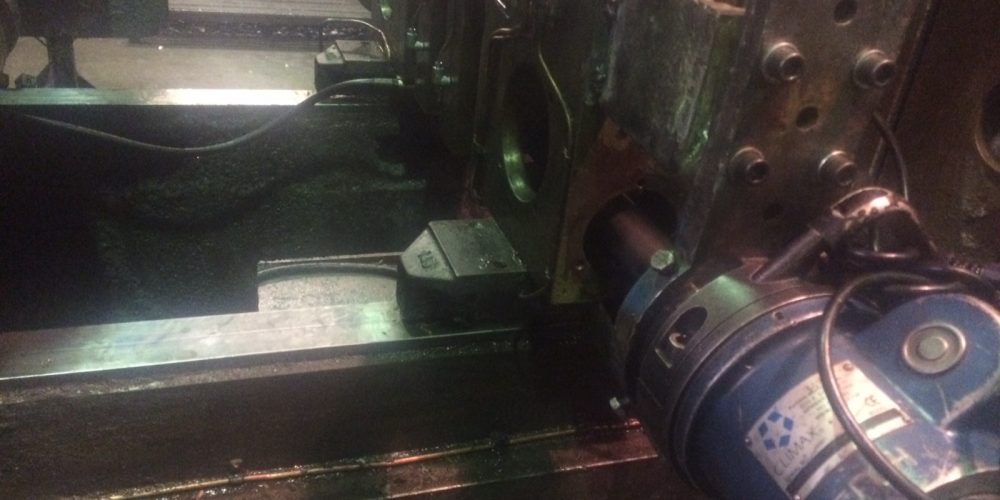

Specialists of WWTECH thanks to on site machining solutions and making precise coordinate measurements restored the right working of the locking system in the molding press.

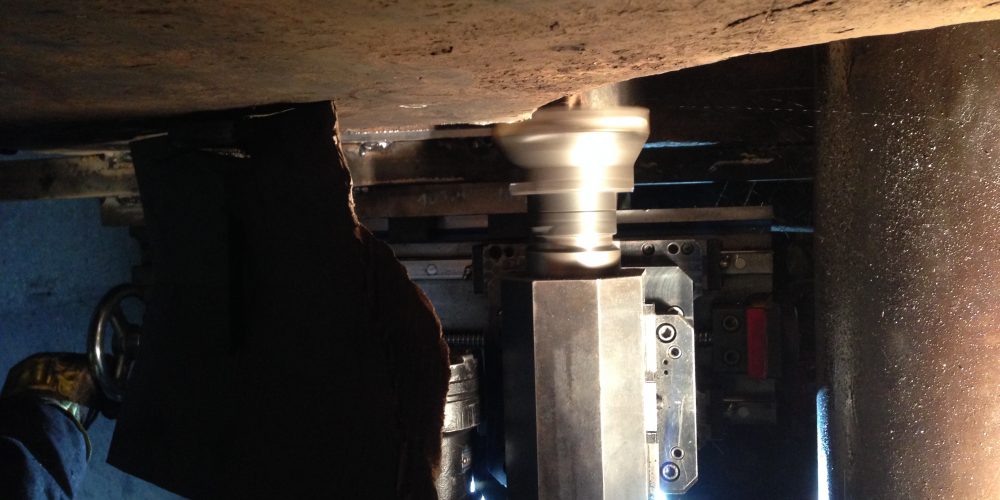

The lack of shape mistake of groove and of center hole of traverse is a condition of the right operate of press forging.

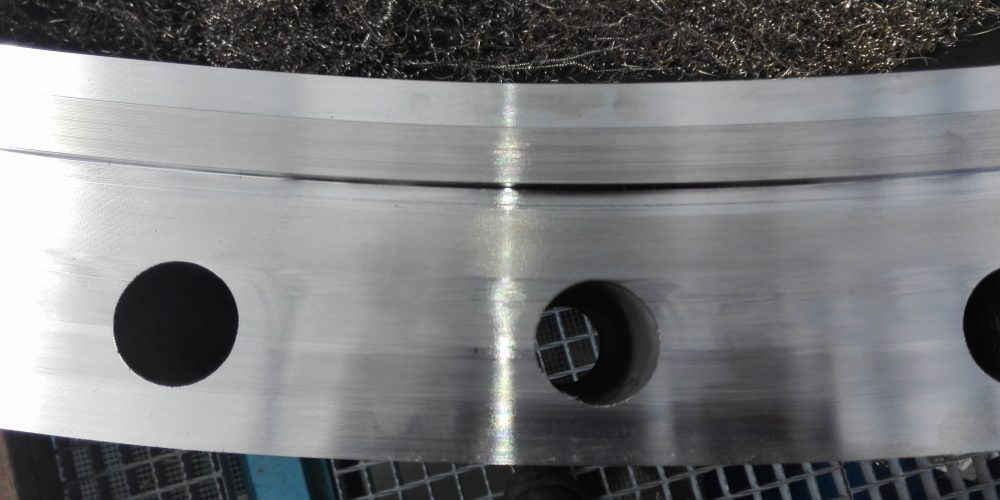

The pads on the heat exchanger flanges – On site machining WWTECH carries out the works in ORLEN Group plants.

Thanks to use on site machining technology WWTECH Services team has done machining of face on the cover of container in petrochemical plant The container modernization by using on site machining let additionally secure it against depressurization. It is extremaly important by virtue of combustible and explosive material.

From 10th to 12th October 2016 in Montreux (Switzerland) was The Conference HYDRO 2016. It is the most important event in Hydroenergetic branch in Europe and over the world. At this conference companies work on hydropower and connected with this branch presented their solutions, experiences and new plans. At the Lake Geneva talked about chances and problems this more and more popular energy source.

WWTECH SERVICES has completed the design of accurate machining with the use of portable devices on the Polish missile frigate ORP Gen. K Pułaski. The works have been performed in Nauta Repair Shipyard. ORP Gen. Pułaski is 135.6 meters long and almost 14 meters wide. The ship was donated to the Polish Navy by the US government. It is guided missile frigate of Oliver Hazard Perry type (OHP). The main purpose of the vessel is looking for and combating of the submarines, forces of aircraft attack and surface ships, as well as defending its own ships and patrolling of the communication routes. The vessel started up polish naval flag 15 […]

WWTECH completed another project of machining with the use of portable devices to the most famous Polish quardship ORP Ślązak. The works were carried out in Gdynia Naval Shipyard. Construction of Ślązak shipquard has been going on for 14 years. In 2001, the Polish government launched a program of “Rook” which was to provide 7 modern corvettes for the Polish Navy. Finally, only one ship was left , its completion would cost 1.1 billion dollars. The Ministryof National Defence decided not to finish this vessel and the finished hull, which 400 million zloty was nvested, was intended for the construction of the ORP Ślązak. See also the launching of the […]

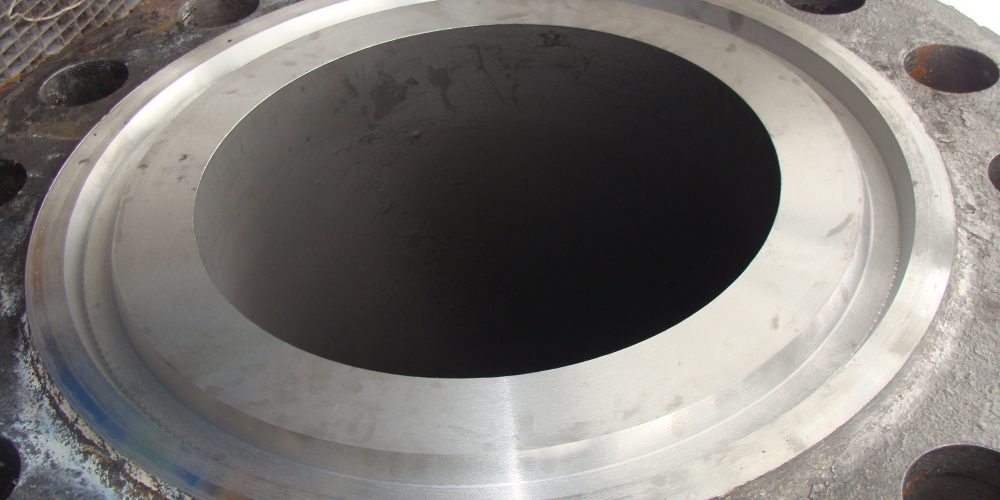

WWTECH SERVICES company has completed the repair project aimed at regeneration of the sealing surface. The works were performed on the element of the turbine set in the power plant in Konin. This is another interesting realization after the projects in the conventional power plants in Opole, Belchatów, Kozienice, Oulu in Finland or Kostolac in Serbia. Konin power plant is the oldest such institution in Poland, fired with brown coal. It belongs to the Group ZE PAK Inc. Its work in the open cooling water circuit is based on a system of five lakes connected by canals. It also performs a function as a power plant for the city of […]

WWTECH SERVICES has performed all accurate machining on the buoy and turret structures of the Martin Linge project implemented by Energomontaż Północ Gdynia for National Oilwel Varco (APL). Machining works were based on the technology of WWTECH company, specially designed and adjusted portable machines. Our quality control department has taken care of the works accuracy which is equipped with modern measurement system. The elements to mine oil are buoy and turret . The total weight of the structure is more than 500 tons, the elements are 18 m high and 15 m in diameter. This is another very complicated machining project which was realized for the EPG based on the […]