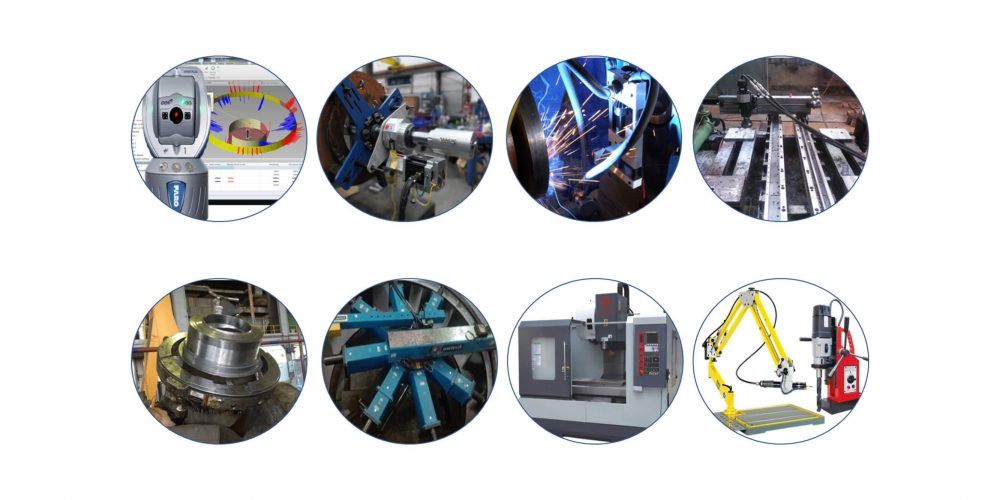

Well-made measurements – quickly, accurately, repetitively – are a necessary condition of successful project. Two things are necessary for this: appropriate measuring equipment; trained and experienced staff. The measuring equipment must meet a number of requirements related to the nature of the work: most often there are remote measurement, resistance to humidity, dustiness and temperature changes. These requirements are met by Laser Tracker ™, which we use in our work. The measurements can be systematized as follows: For the needs of mobile machining: Before machining: initial dimensions and dimensional analysis – determination of allowances, determination of axes and theoretical points, marking out; During machining: dimensional inspection, necessary adjustments, forecasting of work progress; After processing: final dimensions, reporting; Metrological assistance: The service consists in performing measurements for disassembly and assembly works, including mobile machining; Assistance may cover the whole period of activities on the site; The result is ad hoc reports […]

Chemical Industry is very demanding customers. We are therefore glad that we are often chosen to carry out mobile machining services on elements of chemical installations. In this case, it was a heat exchanger on which we made three treatments: facing the face of the flange connection of the bottom of the heat exchanger and planning the face of the outlets together with machining the groove for the RTJ type seal (RT). While flanges planning is typical, routine work, the groove for the steel seal is a challenge – the requirements for dimensional accuracy and surface quality are much stricter than for other treatments. Confirmation of the right parameters of […]

In an unusual scenery reminiscent of the Star Wars droid factory, a small project for the implementation of a new splineway was carried out recently. During the exploitation it turned out that the sunk key connection is destroyed, and the current groove in the shaft so permanently deformated that it can no longer fulfill its role.

For those interested in the themes of mobile machining we have launched the movie channel on YouTube. For now, the offer is very modest, but over time we will progressively complement. We encourage you to watch and subscribe LINK

We have recently completed the provision of services for the construction of a ship to service drilling platforms – a floating platform. The ship was built in Poland for the German-Spanish shipowner, with our modest participation. In the scope among otherscoaxial boring of various sizes of holes and milling of large flat surfaces.

We are pleased to present a short company presentation ‘2019!

Initially only for our own, more and more and more often, we produce special fasteners (not standardized). In our case, our own needs mean mostly customizing mobile equipment to specific cases of service – adaptation the machine to the workpiece, clamping of machining tools, supports or additional bearings. It turned out that there is a demand for such items, usually previously not foreseen, during dismantling or after treatment. A typical example of such a situation are works by flange connections, when it turns out that some of the screws are simply stuck, and hence, must be destroyed when dismantling. To meet the expectations, having gathered a lot of experience, we are now able to offer a more comprehensive approach to widely understood screw connections, ranging from dismantling, including disassembly of the destroyed (rough, worn off, blocked in any way) the screws and studs, through correction of geometry and surface quality of the connection, the correction of damaged […]

Autumn in hydropower is often the necessity of post-seasonal repairs. As usual, a major part of our volume is work for hydropower. In recent weeks, it was the PGE Dychów Power Plant (88 MW) and PGE Solina (199 MW) as well as the Bulgarian Koprinka Hydroelectric Power Plant (29.4 MW), located near the town of Stara Zagora. Scopes of work were similar and often performed once more: machining on large diameters. How it done in hydropower

We kindly inform our potential customers representing Defense Industry and Armed Forces that our company has been registered in the NCAGE system (NATO Commercial and Government Entity) under the number 99P0H.

Once again, we are present in Kozienice, where, at the request of GE Power, we perform machining of the K560 turbine’s components. Similarly to Unit 10, last year, unit 9 is carried out overhaul and modernization of the IP module. In our range, traditionally: machining of surfaces on steam pipes connections and valve chambers, bearings seats and seals in bearing pedestals, reconstruction or calibration of threads. Subsequently, honing the clutch holes and a number of small but necessary recesses, millings, holes. An interesting fact this time is a wide range of fasteners – pins, screws and nuts and special caps manufactured by our company. More on this topic soon