Machining of faces

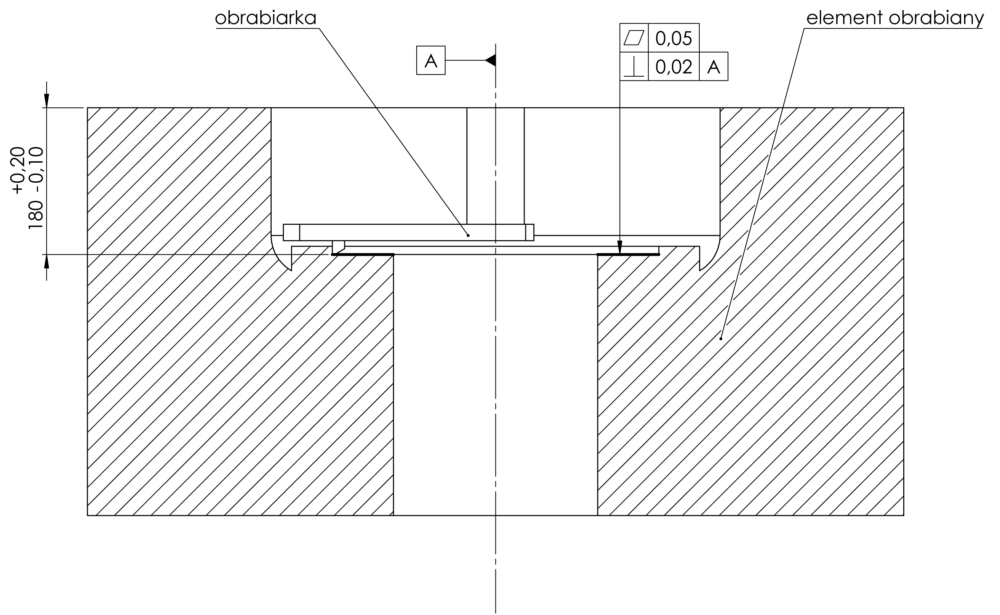

The connection of adjacent elements often found in an unusual position, in hard-to-reach places. For these reasons, ensuring their tightness is extremely important, but much more difficult.

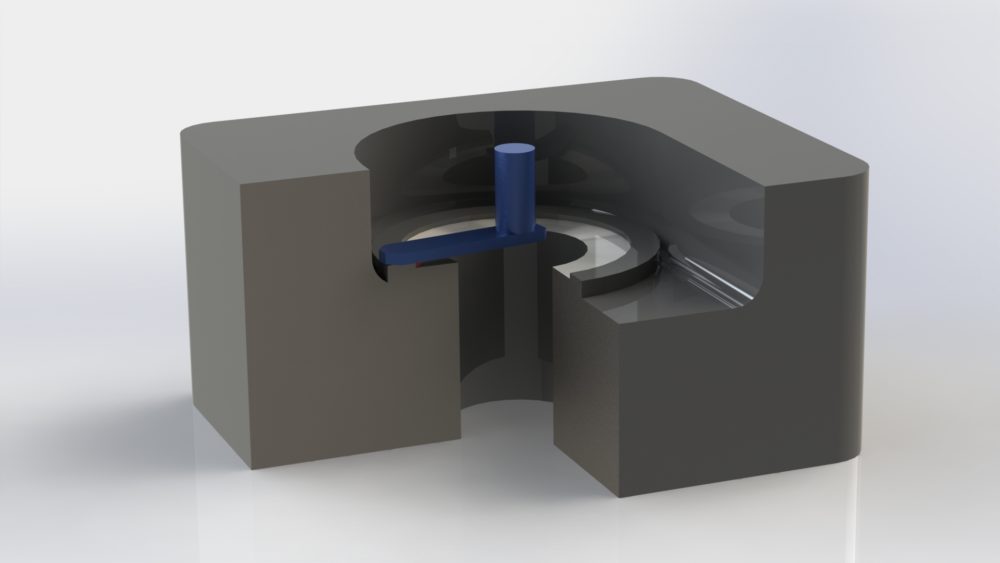

Finding a way to deal with warping, corrosion or regeneration of the space under the sealing rings surface connections, are challenges encountered in each industry. The application of boring as solutions to these problems allows to get the correct angle of convergence with the regeneration of tapered roller faces and restore the demanded tightness on the faces.

With our technology you can also improve the condition of the sealing grooves, the maintenance of the right angles and surface structure, and, in addition, obtain a diameter that is compatible with the original documentation or new guidelines. Precision of applied treatments does not differ from that obtained on the stationary machines, and additional advantages are the time to reach the place of intervention and the omission of the disassembly.