Flat surface milling

The surfaces of these and many other elements are vulnerable to dents, warping and smearing. As a result of operation they often lose their flatness and geometrics in relation to other elements of the system. Sometimes it is necessary to reduce the level of the parts of the machine or the assemble. In this case also it is necessary to use this kind of machining.

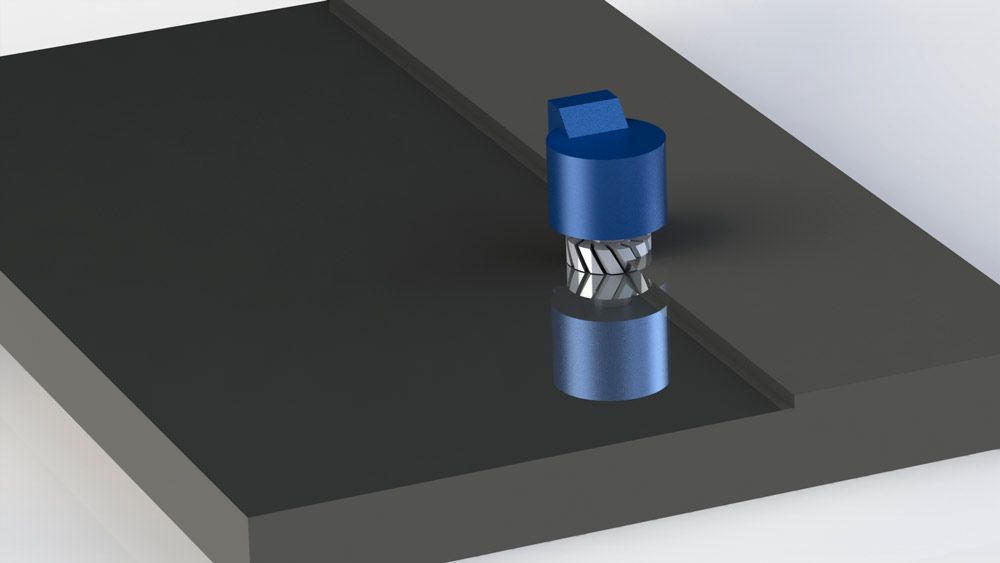

Solution, allowing to guarantee the correct geometrics of both when you create a new design, and the legalization and upgrading existing surface is on site machining. Possession of various types of milling machines that are permanently available team of our experienced engineers to match them to the surface of any shape and size.

Free composing of elements of each machine, allowing us to reach even in hard to reach places, without the need to organise the dismantling and transport of the parts to the workshop. The task does not need unnecessary time and financial effort, the obtained results which do not differ from the most stringent standards, and indicated by the flatness and structure surface.

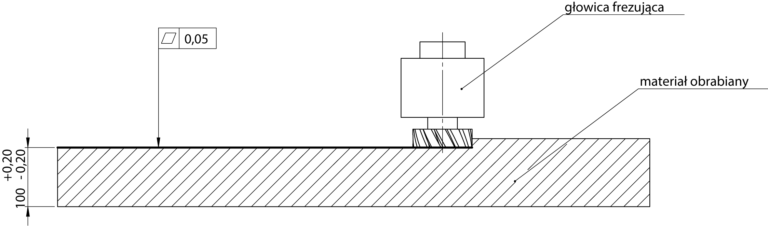

Milling is designed to restore the correct flatness of surfaces, many times it is necessary to meet the tolerances, to correctly comply with its task. Often, however, to reach the surface that requires the treatment and obtain the demanded parameters is related with overcoming many obstacles.

Surfaces, which require precision, mechanical treatment are the foundations of machines and equipment, guides and tables on which they are placed and the foundations. Milling also is often required to the individual components of these machines and installations, such as faces, shared elements, flanges or fragments of stamping dies.