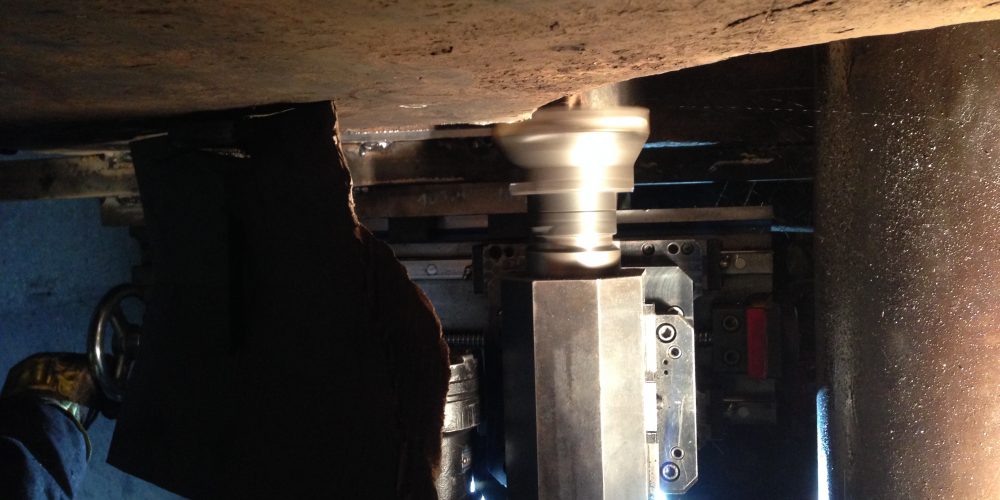

Solutions of „in-situ” maching created by WWTECH Services’ engineers let restore the delivery condition of threaded connections in final drive for roll stand.

The lack of shape mistake of groove and of center hole of traverse is a condition of the right operate of press forging.

WWTECH SERVICES has performed all accurate machining on the buoy and turret structures of the Martin Linge project implemented by Energomontaż Północ Gdynia for National Oilwel Varco (APL). Machining works were based on the technology of WWTECH company, specially designed and adjusted portable machines. Our quality control department has taken care of the works accuracy which is equipped with modern measurement system. The elements to mine oil are buoy and turret . The total weight of the structure is more than 500 tons, the elements are 18 m high and 15 m in diameter. This is another very complicated machining project which was realized for the EPG based on the […]