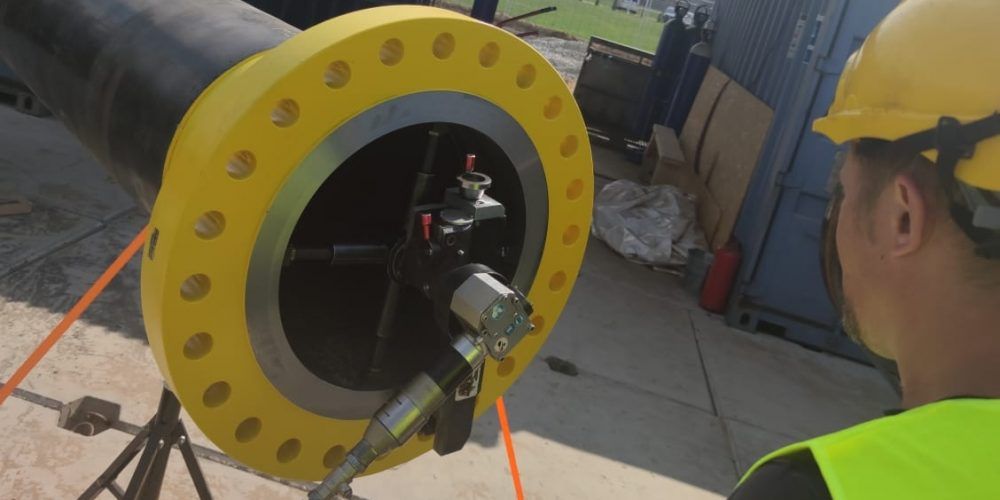

A Rotary Air Preheater is a rotary heat exchanger in which heat exchange takes place thanks to the heat capacity of slowly rotating elements – sheets placed on the rotor. These elements take over the heat from the flue gases from the boiler (they heat up) and transfer it to the air sucked in from the environment, next directed further to the boiler burners. Thanks to the use of OPP, the efficiency of the installation is significantly improved by recovering a large part of the heat from the flue gases. OPP is used in virtually all solid (coal) fuel boilers. Our scope included machining work in four holes: rounding/turning of the hole to size Ø615H7, facing from approx. Ø120 mm to Ø 615 mm with allowance 50 mm (very large allowance!), production and assembly of centering sleeves, drilling and threading holes in the heater body and covers.

A large scope of works related to the main overhaul of the device. Facing approx. Ø1000mm Lock turning approx. Ø1000mm Facing approx. Ø500mm Turning the diameter approx. Ø500mm Turning the diameter approx. Ø600mm Facing approx. Ø600mm Turning the conical surfaces of the body and cover approx. Ø1900 mm

The heavily damaged surface of the journal is salvageable! If the scratches are too deep and it is possible to make mating elements (e.g. bearing shells) on a slightly smaller shaft diameter, then turning is enough to remove scratches and grooves and obtain the right surface quality. If it is important to maintain the original diameter, the turning operation must be preceded by premachining (optional) and layer welding. Only then can the original geometry be restored. We implemented such technology, for example, in the Bujagali power plant, Bujagali HPS, Uganda | WWTECH – On site machining In both cases, the last step of treatment can be honing using the same […]

This time the faces of flanges – pipes of the gas collector. A task very similar to the one recently carried out: Flanges’ faces machining | WWTECH – On site machining

The purpose of standard flange machining is to obtain the correct flange geometry: flatness of 0,05 mm, perpendicularity to the axis – not more than 0,02 mm, and, importantly, adequate surface roughness (< 3.2 μm) More: Machining of flanges | WWTECH – On site machining

In order to obtain the desired state of dynamics of the device, it is first of all necessary to take care of the quality of the foundation, i.e. the adherence of the device base (flaps) to the foundation plate. It is important to maintain the flatness of the foundations plates, but the second, often forgotten, and an extremely important parameter is the deviation of the position of the foundation plate plane in relation to the basic plane, i.e. the sea level plane (water level). In this case, the total deviation of the flatness and level shall not exceed 0,05 mm/m.

Kayrakkum Dam (Russian: Кайраккумская ГЭС; Tajik: НБО Қайроққум), also spelled differently as Kayrakum, Kairakum, Qayraqqum or Qayroqqum, is a dam on the Syr Darya River near the city of Kayrakkum in Sughd Province, Tajikistan. It is located on the western edge of the Fergana Basin and forms the Kayrakkum Reservoir. The reservoir supplies water for irrigation, mainly in Uzbekistan in the lower reaches of the river, and for the production of hydropower. The power plant has an installed capacity of 126 MW and is operated by the state-owned operator Barki Tojik. Construction of the dam began in 1952. Six units with Kaplan turbines were commissioned in 1956 and 1957. The power plant is currently undergoing modernization and renovation, aimed at increasing the power plant’s capacity from 142 to 174 MW. At the invitation of GE, the supplier of new turbosets, we perform machining on subsequent six blocks. We have just finished work on unit 5, the second of six being machined by ours. There are four more blocks ahead of us. In the scope of machinig: machining of the upper and lower ring, faces and cyllindrical surfaces, […]

Bujagali Power Plant is a hydroelectric power plant on the Victoria Nile, a place considered the beginning of the great Nile River – near the beautiful Bujagali Falls in Uganda. Construction began in 2007 and was completed in 2012. The power plant has a capacity of 250 megawatts. The Bujagali Power Plant was uganda’s largest source of energy when it was commissioned. GE supplied all electromechanical equipment – including five Kaplan turbine-generator units with a capacity of 50 MW each, control and protection systems and other power plant equipment. GE’s Kaplan turbines feature adjustable rotor blades and adjustable steering blades that enable them to efficiently deliver power over a wide range of flows, where river flows vary greatly depending on the season. More about power plant equipment: Bujagali – Flawless project execution | GE Renewable Energy About the Bujagali hydropower project – AKDN This time, at the invitation of GE, we performed […]

Borgforsen is a small 26MW hydroelectric power plant on the Fjällsjöälven River in central Sweden, equipped with Kaplan turbines. Two tasks: line boring of holes for guide Vvanes turning the spherical part of the rotor chamber. Insofar as reaming is a standard activity and performed by us many times, the turning of the spherical part was for the first time made with a new machine of our own construction.

Rana Power Plant is located near the town of Mo I Rana, in central Norway . It operates with installed capacity of 500 MW in four units with Francis turbines, with an average annual production of about 2100 GWh. The station is owned by Statkraft. In terms of annual production in Norway, the Rana power plant is second to the Svartisen hydroelectric power plant. Photo: Rana Power Plant outside and inside In our range there was machining of axuial, radial and conical surfaces within the head coverthe bottom ring. A certain challenge was to turn the over five-ton machine by 180° without access to the crane – only with the help of hoists. This operation can be seen in the video: