Bujagali Power Plant is a hydroelectric power plant on the Victoria Nile, a place considered the beginning of the great Nile River – near the beautiful Bujagali Falls in Uganda. Construction began in 2007 and was completed in 2012.

The power plant has a capacity of 250 megawatts. The Bujagali Power Plant was uganda’s largest source of energy when it was commissioned.

GE supplied all electromechanical equipment – including five Kaplan turbine-generator units with a capacity of 50 MW each, control and protection systems and other power plant equipment.

GE’s Kaplan turbines feature adjustable rotor blades and adjustable steering blades that enable them to efficiently deliver power over a wide range of flows, where river flows vary greatly depending on the season.

More about power plant equipment:

Bujagali – Flawless project execution | GE Renewable Energy

About the Bujagali hydropower project – AKDN

This time, at the invitation of GE, we performed three tasks:

- removal of blocked screws, reaming threads in the ceiling position, on a several-meter-high platform.

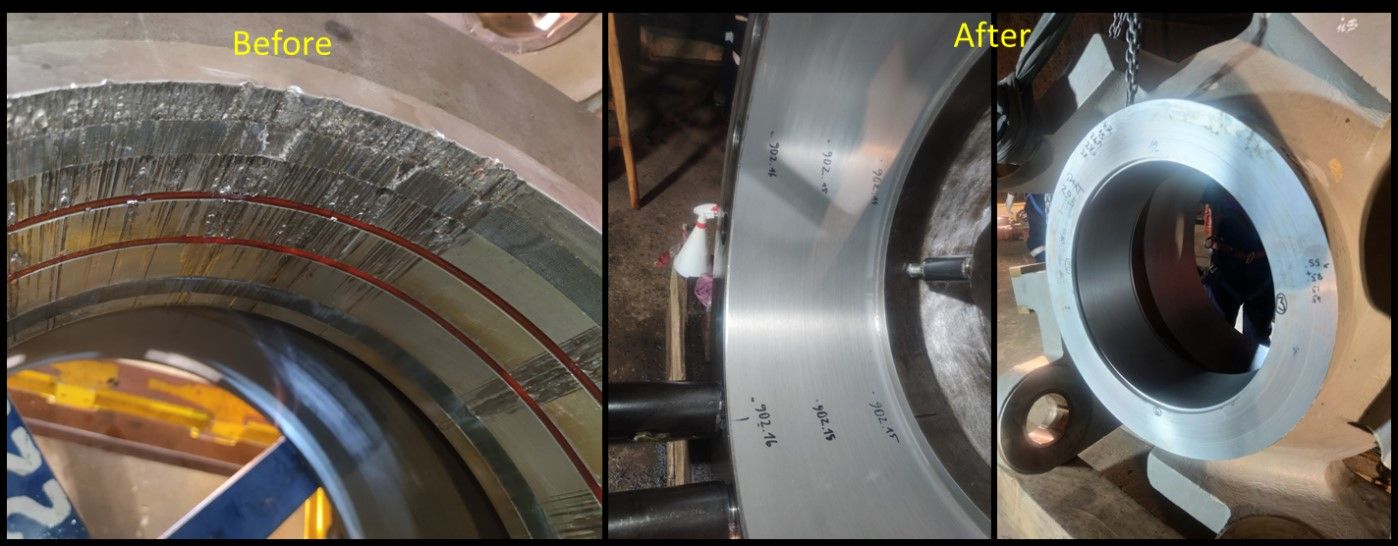

- a Ø500 shaftt in the hub of Kaplan’s turning to remove the seizures. The cavities were welded, after which we reworked the surfacing area.

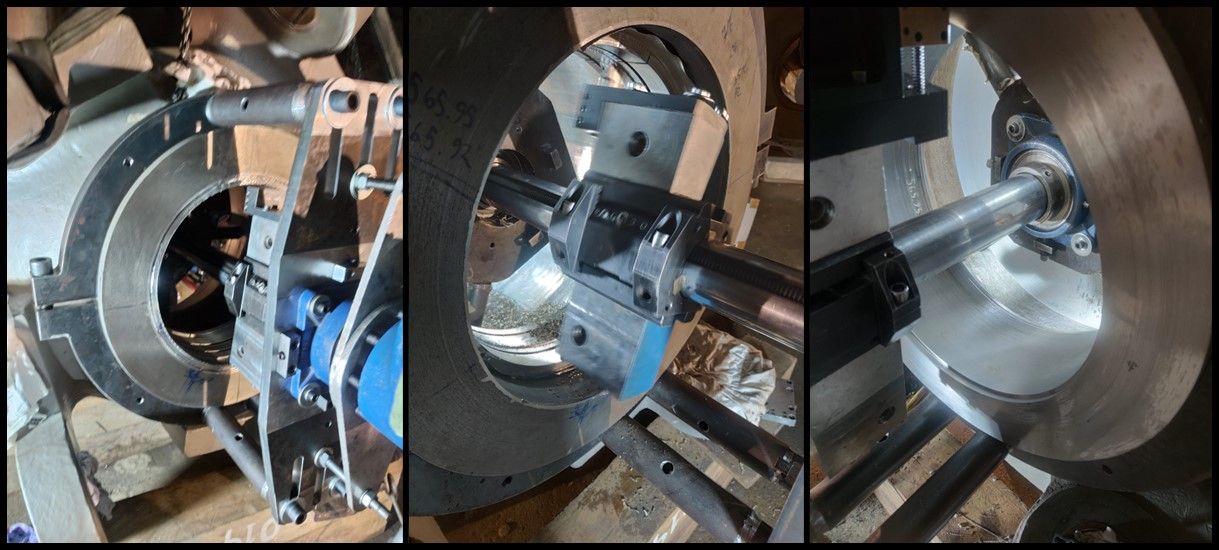

- complex machining of the servo motor body (device responsible for the position of the Kaplan turbine blades): cylindrical Ø560, Ø 900, frontal surfaces, and above all the insertion of the insertion press-fit bushing on the diameter of Ø560.

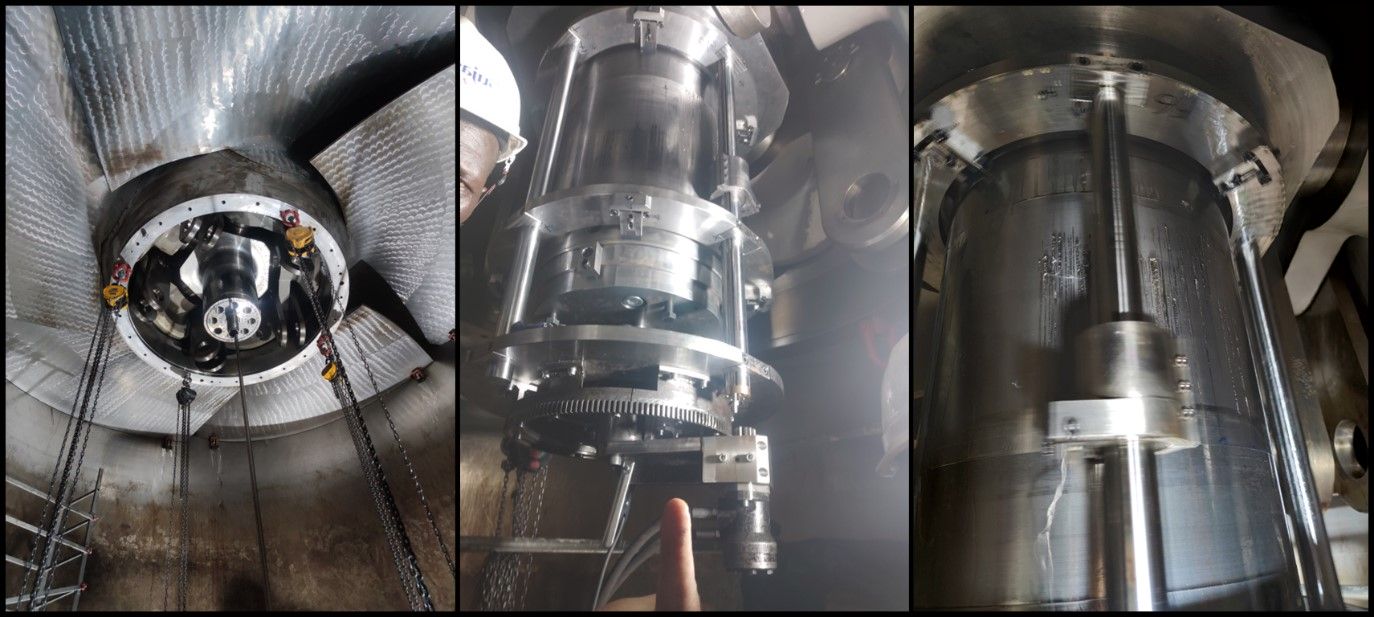

The task would be almost standard, if not for the fact that the processing took place in a concrete pipe channel, 15 meters below the surface, and the only entrance was so tight that the oil aggregate had to stay outside. The machine tools also had to be adapted to be moved through a tight communication channel.

The machining was preceded by dismantling the device; in terms of also usuwe pounded blocked screws.

Then, after exposing the machining site, we installed a machine tool of our own design – OTM (Orbital Turning Machine).

And here is the end result:

Place of processing of the servo motor body – water channel.

Processing of the servo motor body. Since the customer did not agree to weld the fastening structure of the machine tool, we installed it using special clamps.

And here is the end result: