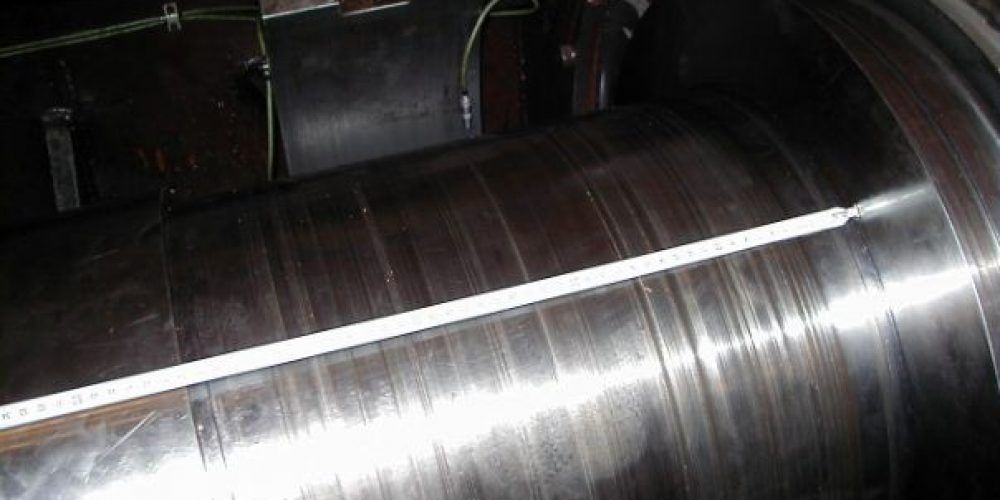

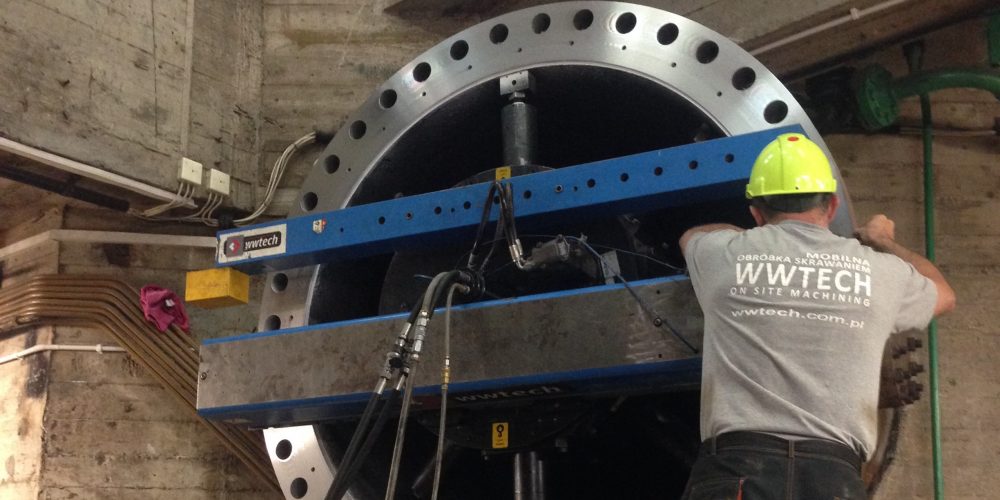

Failure of the oil system can have serious consequences. In this case, the bearing journals have been very seriously damaged. However, it is unusual that the scratches caused by the friction in the dry bearing were more than 2 mm deep. The repair consists in turning and then honing the surface of the journal. In this case, due to the depth of the scratches, it lasted several days. More about such work: https://wwtech.com.pl/en/2020/02/04/drums-shafts-and-journals-turning/

WWTECH team again was a contractor of works, where the time of reaction and quality of the execution were the key parameters of the Contractor choice.

Solutions of „in-situ” maching created by WWTECH Services’ engineers let restore the delivery condition of threaded connections in final drive for roll stand.

WWTECH Services team has made an legalization of cut-valve’s surfaces in pumped storage water power plant in Poland.

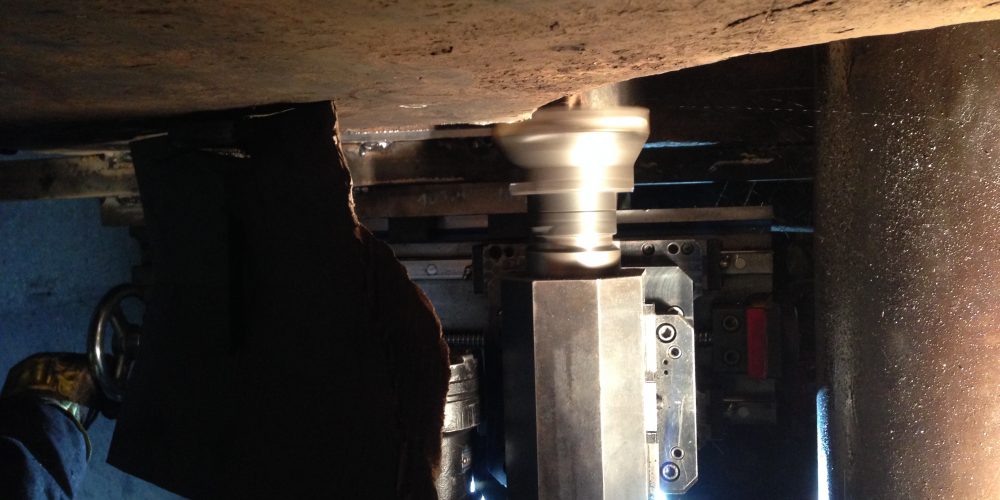

WWTECH was done the machining of the key surfaces in steam turbine’s cut-off valves.

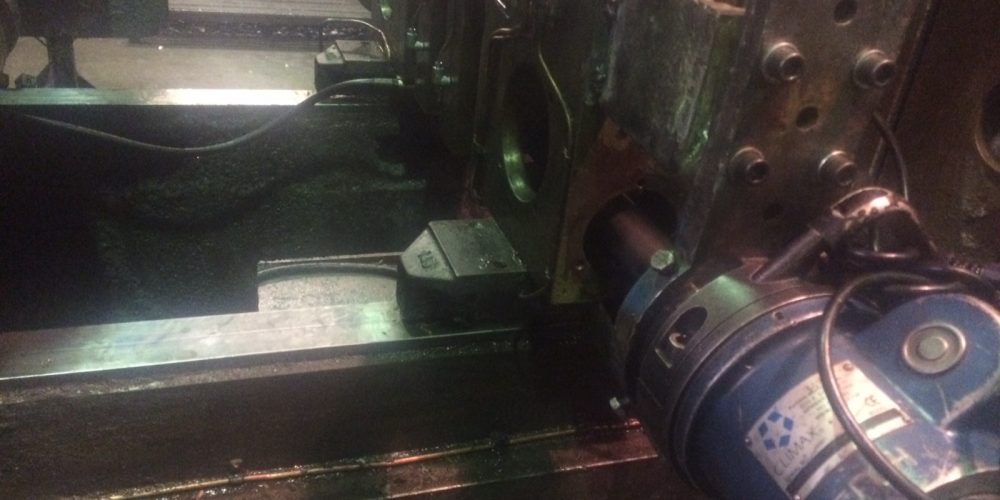

Specialists of WWTECH thanks to on site machining solutions and making precise coordinate measurements restored the right working of the locking system in the molding press.

The lack of shape mistake of groove and of center hole of traverse is a condition of the right operate of press forging.

WWTECH SERVICES once again have taken part in the scientific and technical conference, organized by the BMP publishing. This conference is an event gathering industry professionals. It allows for the exchange of experience and familiarization with new technologies and technical guidelines. The leading topics were: The way for the effective maintenance management The way to support the engineer. Systems and tools to support the work of R&M services. The way for a longer work of the installation. How do we exploit it to work longer? Reapair downtime of installation. Management of renovation project in practice. The way for renovation. Adjusting of the repair policy to the plant strategy. The way […]

WWTECH SERVICES completed the task to restore the tightness on one of the pressure valves in the steam turbine group of conventional power plant. The machining and repairing work have been carried out without the need for cutting and transporting the element to the workshop, which have allowed for a quick restoration of normal housing tightness and restart the operation of the whole plant. Our technology is the support for keeping the operation of industrial plants that need immediate action.